Do you want to automate your manufacturing business? This article offers a detailed insight into the core concepts of automation for manufacturers.

Automation in manufacturing is the process that is behind the tremendous economic miracle encountered by the modern world in the last 100 years. In this regard, flexible automation is among the best ways to raise the productivity of labor for the majority of the participants on the market. Why is this technology so vital? In our opinion, it reduces the risks of human error, which are common regarding tedious tasks of various kinds. Programmable automation removes many of the manual jobs and allows companies to transfer their employees towards tasks that require a much larger degree of creativity. Since the nature of automation technologies is ever-changing, modern production specialists in the manufacturing sector need to clearly know what technologies are currently dominant in the manufacturing automation market.

Explaining Automation in Manufacturing

Let’s start with explaining the essence of automation solutions in manufacturing software development. Automation involves the substitution of human labor with machine labor. A common misconception is that machines completely remove labor. In reality, this is far from being the case. Instead, automation and robotics are the transformation of human labor process towards something more complex and creative. Machines work only if there’s human intervention involved because even the most advanced AI systems these days don’t possess the ability to analyze various production situations as well as humans do.

The main advantage of production lines is that they allow one worker to, for instance, start producing 100 units of the same ware at the same time, in opposition to 10 units in the past. This aspect of the manufacturing industry is undoubtedly one of the core reasons why so many companies are willing to invest in it. There’s always a capacity for monumental improvements in long-term productivity.

Benefits of Automation in the Manufacturing Industry

Implementing automation in manufacturing is necessary for offering various companies a tremendous amount of long-term benefits. Let’s take a look at those core benefits:

1. Overcoming labor shortages

Currently, the world is encountering progressively larger labor shortages. This happens for a multitude of reasons. Firstly, a major issue is the fact that talented employees will always remain scarce, regardless of the changes in the economy. The Pareto principle clearly showcases that the most productive members of the population represent only 20% of its scope. Secondly, the constant growth of global companies and competition between them also creates additional pressure on the labor market. Lastly, there’s also a large-scale problem influencing the labor market: global fertility rates are declining due to the spread of education and growing living standards. Considering the third factor, it’s inevitable that labor shortages are likely to grow even further unless the population decline trend is reversed by some now-unknown economic or extraeconomic factor. In this light, automation tools are among the best ways to overcome the presented problem.

The cost of labor will likely grow in the upcoming decades due to labor shortages. Machines can be a perfect way to navigate the business world in light of the presented trend. The upcoming years will see major investments into automation that will allow humankind to produce even more positive changes both in profit rates and in the overall availability of various goods to the general populace. Why are machines ultimately so vital? They allow companies to rely more on talented individuals who get to exhibit a much larger impact with novel technologies. More importantly, they enable companies to rely on a generally smaller workforce, solving the problems presented above.

2. Increased safety

One of the core problems with manufacturing is that many of the manufacturing tasks involve equipment that can injure the workers if not controlled properly. Of course, it’s possible to significantly reduce work-related trauma by following stringent safety regulations. But even the strictest regulations can’t prevent some cases of work-related problems. What can prevent those problems is the use of novel technologies. We can use machines such as industrial robots to completely exclude human labor from complex tasks that can pose danger to human health. The 20th century saw a major transition to automated labor.

Among the chief outcomes of this transition was the major reduction of work-related injuries (obviously, an investment into work safety also played a major role). For this reason, we’re highly optimistic about robotics and Robotic Process Automation in the upcoming years. This process will reduce work-related trauma even further, making the future of labor in the manufacturing sector safe and comfortable for all the stakeholders.

3. Increasing productivity

While the long-term reason to invest in different types of automation in manufacturing is the growing labor shortages, there are also major short- and medium-term motivations to consider a move towards this type of technology. What are those? Productivity growth. The history of global technology is staggering if one reviews its impacts. For the majority of human history, global GDPs stayed at the level of 1000 to 1500 US dollars per person.

Right now, the majority of the countries in the world manage to offer living standards that are at least two times higher. The U.S. GDP per capita is 70 times higher than what the world saw a mere 500 years ago. What’s the core driver of this impressive growth? Our ability to produce more wares faster. The transition towards higher living standards occurred when legal and population structures incentivized investment into machines. Investment into manufacturing automation is, thus, primarily an opportunity to participate in this massive growth of human wealth.

4. Reducing worker cost

Machines represent a labor-substituting factor. In this regard, their core capability is to help companies transition from the expansion of the workforce to the improvement of productivity. Under the assumption of no technological growth, any rapid expansion of various companies would have been more or less impossible because they would have been limited by the capabilities of their human workforces. Manufacturing process automation resolves this problem by allowing various businesses to produce as many wares as in the past with smaller workforces. This labor-economizing capability of automation in manufacturing is highly vital because it reduces worker costs, allowing companies to expand profit and, ultimately, share the benefits of their growth with the whole society. Automation allows us to produce more wares at a lower cost.

5. Improved data analysis

A major problem of economic planning, as Friedrich Hayek, a famous Austrian school economist, claimed, has to do with the fact that it’s difficult to collect so-called tacit information. Employers operate in conditions where it’s impossible to control every action of an employee. In this light, the goal of automation doesn’t lie solely in improving productivity. Automation removes the human factor from work and, in combination with various computers, allows companies to receive more information on their production processes. In short, industrial automation is a tool that allows companies to better plan their production, overcoming a large number of unexpected aspects of the manufacturing process that negatively impact firms without major investments into the automation sector.

Examples of Industries That Focus on Manufacturing Automation

There are multiple industries that focus on some type of manufacturing automation. Here are the fields that use all types of machines and other important frameworks to improve their overall productivity levels:

- Automotive: Robotic automation for welding, painting, and assembly.

- Electronics/Semiconductor: Automated assembly, testing, and packaging of components.

- Food and Beverage: Automated packaging, bottling, labeling.

- Pharmaceutical/Medical Devices: Automated drug formulation, packaging, sterilization.

- Aerospace/Defense: Automated manufacturing of aircraft/spacecraft parts.

- Plastics/Rubber: Automated injection molding, robotic material handling.

- Metal Fabrication/Machinery: CNC machines, automated welding, robotic handling.

- Textile/Apparel: Automated knitting, weaving, sewing machines.

- Chemical: Automated processing and material handling.

- Furniture: Automated woodworking, assembly, finishing.

- Printing and Publishing: Automated printing presses, binding, finishing.

- Glass and Ceramics: Automated glass forming, ceramic molding.

What Types of Automation Exist in Manufacturing?

In our opinion, the following types of automation are highly prevalent in manufacturing:

Fixed Automation

Fixed automation is the use of large-scale equipment that can quickly perform one or several actions. This approach is great for the mass production of one core product. Examples of fixed automation can be found in factories that mass-produce certain goods. They’re popular in car factories and various food production facilities. These automation systems are necessary in fields without major change to products: their core problem is the lack of flexibility.

Programmable Automation

The extension of programmable automation involves reprogrammable machines that can handle genuinely different tasks. It’s suitable for batch production in cases when product specifications change over time. An example of programmable automation is an AI-driven manufacturing machine. You can give it diverse tasks, and it’ll be able to produce certain parts in batches. While flexibility is among the core benefits of manufacturing automation that belongs to this type, it’s slower than fixed automation tools.

Flexible Automation

Flexible automation tools are frameworks designed to easily adapt to certain changes in product design. They work with a wide variety of products and require minimal amounts of time for reconfiguration. A good example of this technology is 3D printing. It can produce almost every imaginable part as long as instructions are available. This technology is, likely, the future of automation. It offers the most diverse automation options for producers. At the same time, the approach is not suitable even for batch production. The core goal of implementing automation in manufacturing that belongs to this type is the ability to create custom parts for certain products.

Manufacturing with computer integration (CIM)

A major type of manufacturing automation is undoubtedly the integration of computers into the whole production process. In this regard, automation can come in two forms. On the one hand, computers connected to various sensors may be used to analyze the existing manufacturing process and later perfect it. On the other hand, there’s also equipment that uses computers as the core control frameworks. For instance, Computer Numerical Control, which we’ll review in the next section of the presented article, represents a perfect example of this approach to manufacturing. You can use computers to configure every aspect of production by, for example, clearly delineating how they should proceed with the processing of raw materials.

IIoT

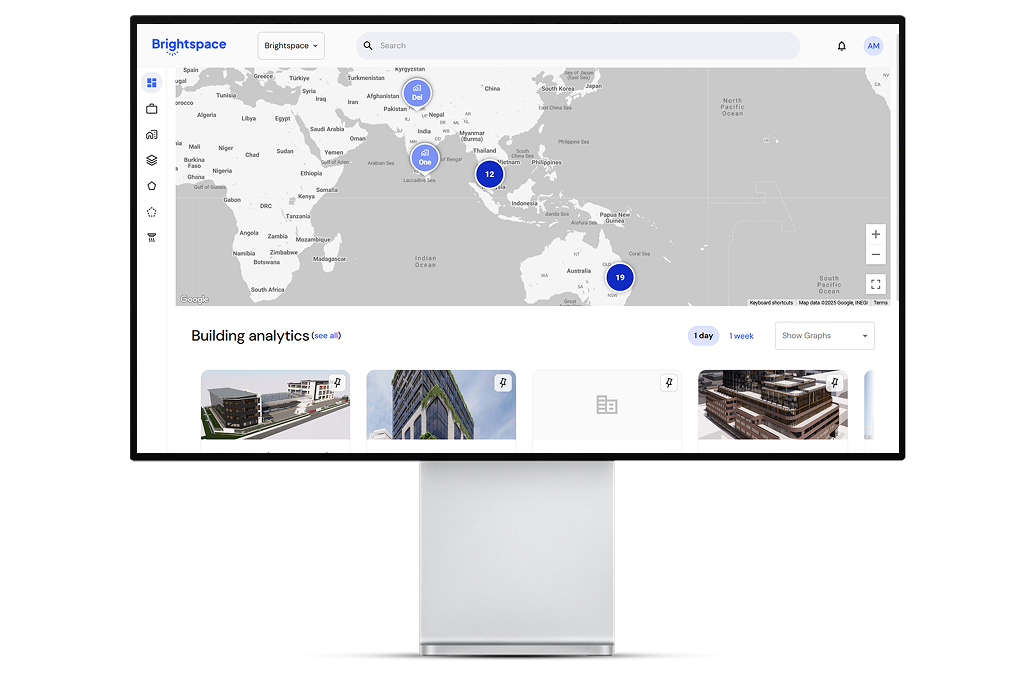

The Industrial Internet of Things is one more technology that is essential for automation in manufacturing. The Internet of Things allows the transformation of common everyday tools into complex mechanisms controlled by computers. For example, IoT screwdrivers can be connected to smartphones for various configurations. How is this technology different from computer-aided manufacturing? Primarily, because it involves a connection to the Internet. While computers in manufacturing are used to, for example, improve the accuracy of production, the Industrial Internet of Things is more useful for data collection. A major aspect of business operations involves the ability to control supply chains of all types. In this regard, IIoT is highly useful when it comes to controlling inventory levels. You can use the presented technology to record the location of various instruments and, thus, prevent major instances of inventory loss.

Hard automation frameworks

The goal of manufacturing automation that involves hard frameworks is about complete control of certain processes. For example, many companies in the chemistry-producing sector are actively using the technologies of this type. Automation can help completely remove human involvement from certain processes. In short, hard automation is automation that minimizes human participation in production, allowing the workers to concentrate on strategic decisions. This type of automation is usually what people think when they hear automation: a complete substitution of human labor with machines.

The problem, however, is that this type of automation is typically limited. It requires many machines that are usually fixed to a certain location and can perform only one type of action. In short, while this type of automation in manufacturing is strong at reducing costs, it also requires major investments into machines that can perform only one activity. Therefore, the presented type of technology is usually used only by the largest companies on the market that can find enough investment funds to purchase the relevant goods.

Programming-Oriented Automation

Some machines allow their owners to program the outcome they want to see, and then are capable of producing certain wares according to the programming. A good example of such machines that are used for automation in manufacturing includes 3D printers. In their case, you can upload a certain template according to which they’ll then produce the relevant wares. Modern production protocols sold on the Internet allow producing myriads of tools for diverging sectors using those methods. These machines perfectly reflect the fact that manufacturing with the help of machines becomes more creative. Instead of producing wares themselves manually, the workers get an opportunity to sculpture a 3D model and then let special production machines reproduce hundreds of similar samples.

Flexibility-centric automation

The preceding approach to automation proves to be highly inflexible in the majority of cases, despite the tremendous production speed. It’s unacceptable for companies that don’t need many wares or tools, but instead require spontaneous production of multiple different instruments. For example, companies that focus on fixing cars may need to invest in the production of multiple parts for their customers, depending on their needs. In this light, an inflexible platform is unlikely to work. Instead, one needs to invest in frameworks that can combine process automation with the ability to change product characteristics. What are some of the technologies that can work well in this regard? A combination of machine learning and CNC machines is a perfect example. The usage of small-scale 3D printers may sometimes be acceptable, too. The core goal of such technology, ultimately, is to enable cost savings for small-scale products.

Specific Manufacturing Automation Technologies

Here is a more specific set of technologies that are being used in the manufacturing sector. As you may see, there’s a very wide range of frameworks to consider:

Robots

The first technology that is often used by various companies on the market are robots. Robots are autonomous machines that can perform a limited number of production activities independently. Robots are currently being used in a wide range of activities. For example, a common use case for robots is to utilize them for transporting various goods. We’re seeing bots that are capable of delivering tools and other important wares independently. Robots are also involved in some production activities. For instance, there are industrialized arm-like machines that can also do many actions in an independent fashion. In short, robots are a perfect type of machine when you need to substitute humans in certain business processes. Their only problem is that they’re typically limited only to certain activities.

CNC machines

CNC machines are an automation technology that allows one to program a certain behavior and then enable the machine to do the relevant work. For instance, you can input certain values regarding the size of a production part and the CNC machine will then act according to your instructions. This type of automation in manufacturing is highly valuable in conditions where you have to produce many instances of one ware, or in situations where you only have one chance to work with a particular material. Using the relevant instructions, the involved machine will then do everything exactly according to your instructions. With proper configuration, the presented machines achieve a level of accuracy that is unachievable for the majority of workers. It’s a great way to make repetitive tasks less tedious and, at the same time, achieve an improvement in the quality of the relevant products.

SCM software

Supply chain management is one more field that benefits from automated systems. In this regard, supply chain management software is an additional type of automation technology. In this case, automation involves the tasks that are administrative in nature. You can use SCM to review what happens in your supply chains and then, more importantly, create records based on the received information. How can those systems work on the presented tasks in manufacturing automation? The answer is simple: they work perfectly in combination with various types of RFID devices and the Internet of Things. These systems are notable for their capability to collect information in an automatic mode, greatly reducing the pressure on the administrators.

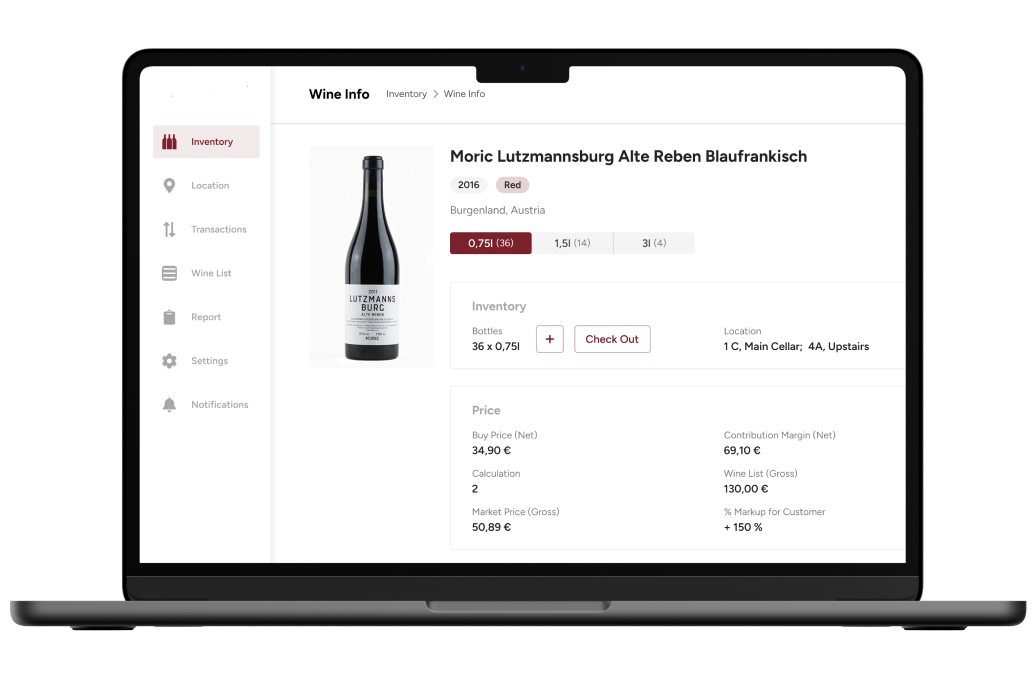

Inventory management apps

Similarly to SCM software, inventory management software achieves its goals by automating the monitoring of inventory status. Instead of having to track what happens to different types of hardware personally, you can offload this task to the relevant apps. Obviously, some human involvement will be vital. However, automation technology nonetheless removes a lot of pressure by, for instance, offering automatic tracking of the machine status. Once again, the presented capabilities of the technology are primarily enabled by the frameworks such as RFID and IIoT.

CAM apps

CAM software is among the core positive developments in the manufacturing sector regarding the preceding 20 years. What is CAM? These are apps that allow you to create detailed models of various products and then import the blueprints into various machines that support the relevant formats. In this respect, the key benefits of the technology are obvious: you can create a complex blueprint of a certain object and then use it for mass production. There’s no longer any need to focus on particular parts: instead, you can create one model and then the relevant machines will simply follow this model. Obviously, everything depends on the quality of the templates; however, several tests are unlikely to have a negative impact on your production capacities in comparison to the manual process.

ERP

ERP or enterprise resource planning is the usage of software for monitoring the majority of the processes in a particular firm. For example, you can utilize ERP software to see the expenditure of a particular material per worker. This information can later be used to upgrade various processes in your firm through technologies such as inventory management automation. ERPs also perfectly integrate with frameworks like RFID and IIoT. They’re capable of monitoring all resources in your firm, providing automation in manufacturing through the steady supply of information.

Product Lifecycle Management (PLM)

Among the key benefits of automation software is undoubtedly its capability to track information that is difficult to monitor for human workforces. In this regard, one of the examples of the relevant automation technology comes in the form of Product Lifecycle Management software. It’s a technology that allows you to monitor the status of your product from multiple standpoints. You can involve manufacturing and marketing departments to provide multiple sources of information on a particular project. Using this information, various departments can then make better decisions. For instance, the knowledge of the reaction to a particular product can later be used to improve particular aspects of it. This data is essential if you want to perform efficient manufacturing automation in your firm.

Accounting software

Accounting software for manufacturing also benefits from the application of automation. How exactly? When you use various systems for monitoring the status of production in your firm, it’s possible to calculate a lot of valuable information for the financial department. Consequently, the monitoring of resource usage in your firm may eventually transfer to accounting automation. It may no longer be necessary to hire large accounting departments, the main goal of which is to obtain important information from the relevant stakeholders in your firm.

Sales automation

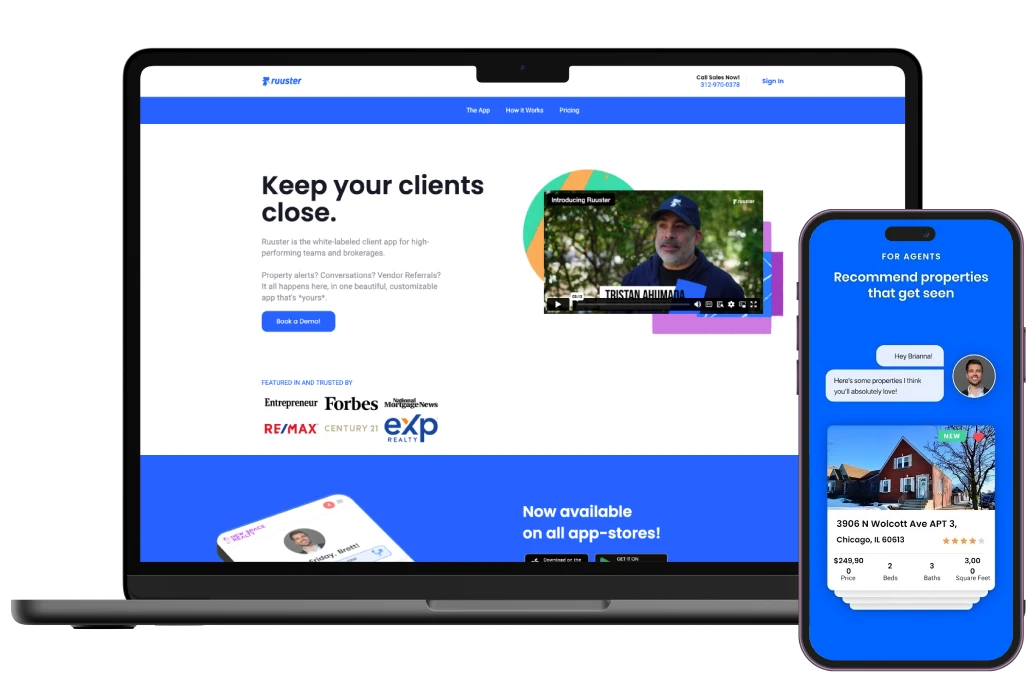

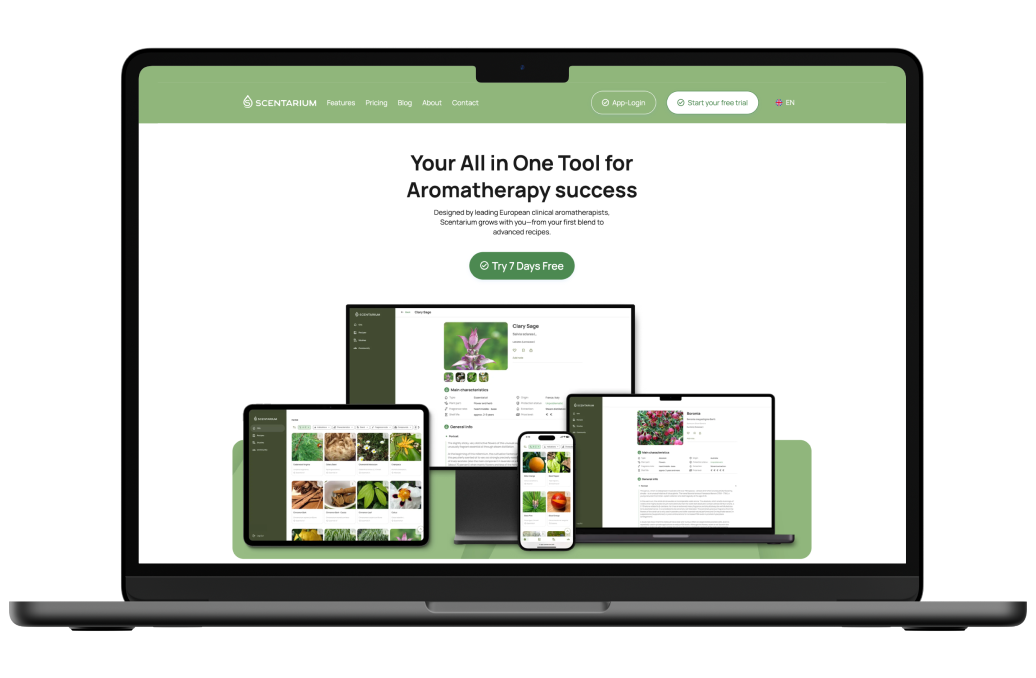

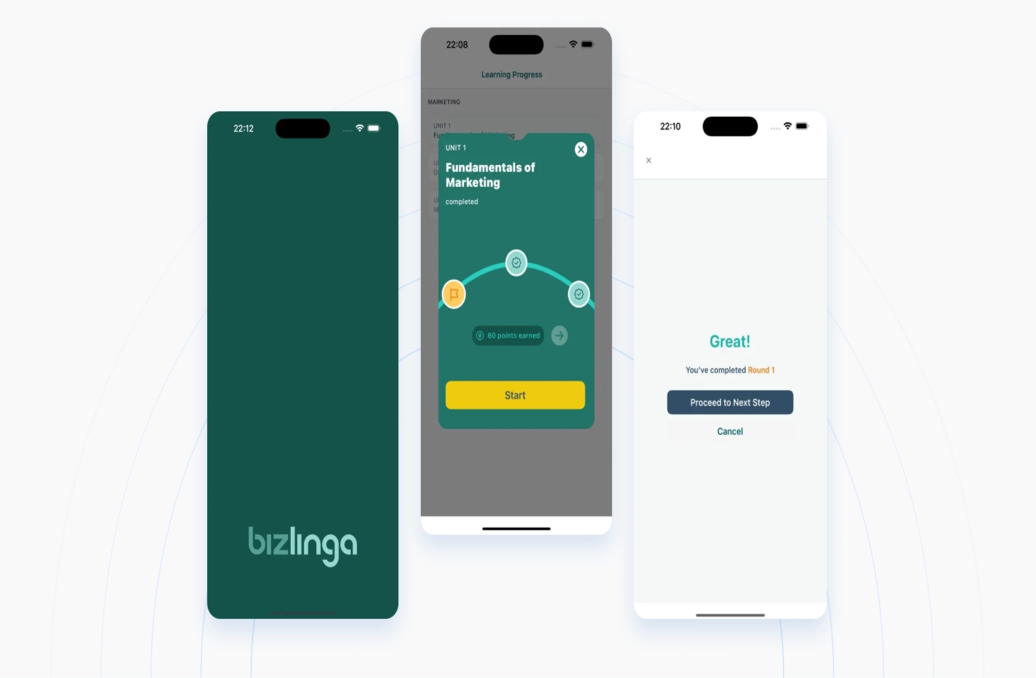

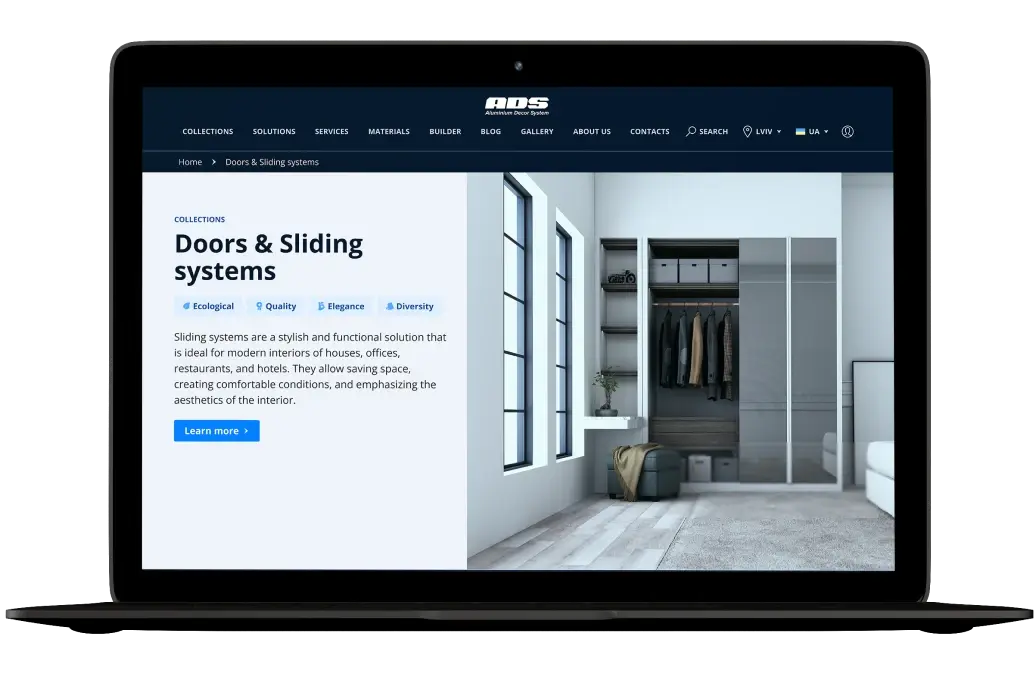

Sales automation software is also essential if you want to work in the manufacturing sectors. Most people think about automation in factory while talking about robots. However, the only way for a firm to profit from certain goods is to actually sell them. Hence, the sales process can be seen as a part of the overall production. In this respect, we’re seeing the rise of sales automation platforms on the market. More and more tools allow diverging companies to sell their wares in a completely automatic manner. Therefore, there’s an opportunity to reduce the expenditure of resources on the presented aspect if you invest into the relevant sector.

Future Trends in Manufacturing

Ultimately, there are multiple future trends that are going to define manufacturing. Here they’re:

Growing connectivity

The spread of the Internet is becoming increasingly unstoppable. More and more locations are receiving access to this technology. This information indicates that we’re nearing a future where Internet connectivity will be all-pervasive. In this light, more and more companies will be willing to use Internet-based innovations. After all, there’s now an opportunity to utilize those technologies even in the most remote locations of the Earth.

Industrial Internet of Things

The spread of the Internet allows modern companies to promote automation in the manufacturing industry through the Internet of Things. The idea is rather simple: most devices now receive microcomputers that enable them to connect to the Internet. Such a usage of the technology offers many great opportunities for relevant decision-makers: for example, it’s now possible to collect much more information than in the past about the work of different machines.

AI

Artificial Intelligence (AI) is one more trend that is going to change manufacturing. This technology will play a major role by, for example, enabling the automatic control of certain machines. It’s also possible to use modern AIs as reference guides for the workers: they can answer complex questions about the usage of particular machines.

Growing skill level of labor

Lastly, we’re seeing a major improvement in the skill levels of labor. Education is becoming more and more widespread. The majority of the population in the world is now literate. Moreover, billions of people are receiving a full-scale college education. This means that the workers capable of using complex real-time machines are growing in number. While this doesn’t solve the problem of labor shortages we mentioned above, such a growing skill level of labor is essential for promoting a long-term trend of automation.

Keenethics can assist with the development of high-quality automation software!