The usual day of an employee working with supply chain management is analyzing a large stock of data and tracking all production updates to make the proper forecasts for market and clients’ demands. All this happens when market dynamics evolve quickly, many alternative products appear, and customers can consider the solution as long as required. How to reach them through production and expand business up to their needs is the objective of supply chain management software.

In this article, we will define the top capabilities of efficient supply chain management (SCM) software, exploring how these key features can streamline manufacturing operations, improve operational accuracy, and enhance decision-making processes. We’ll also spotlight the benefits of SCM manufacturing software development for business owners, showing how it can lead to better customer satisfaction and higher agility in a competitive market.

Understanding the Role of Supply Management Software

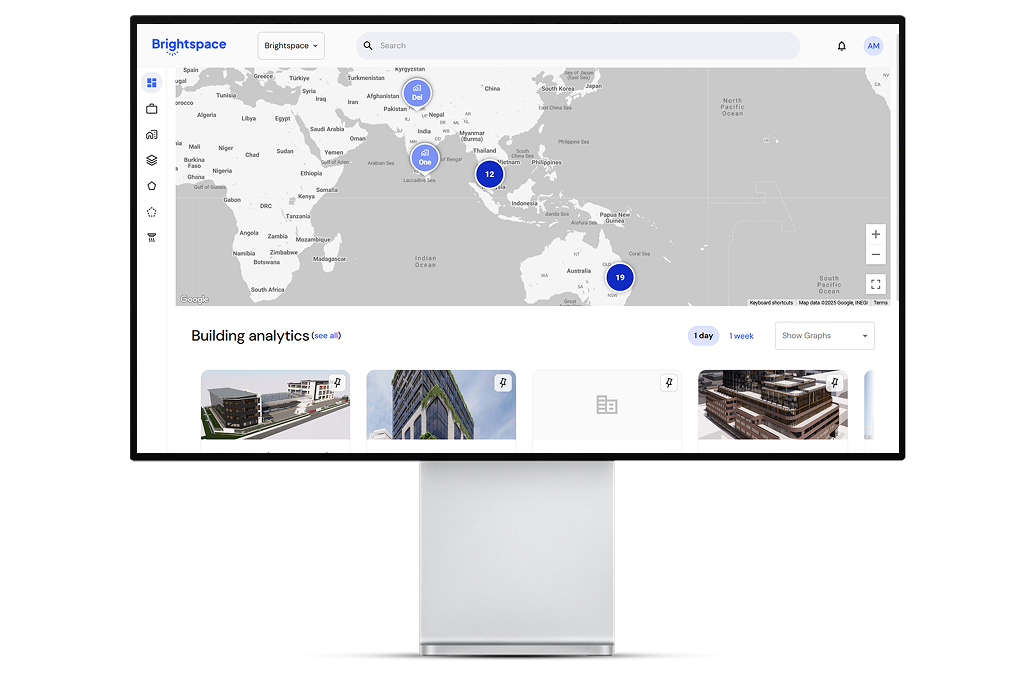

Modern trade crosses boundaries and reaches buyers, logistics providers, and suppliers from around the globe. Managing the supply chain ecosystem is challenging because of the evolving opportunities and operations that manufacturers face.

Supply chain management software solution manages the movement of products and data between manufacturers and consumers. Its functionalities allow employees to manage all supply chain activities, including logistics, vendor management, order changes, and final distribution. The main focus of SCM is to simplify production planning and integrate and manage all supply chain operations to respond efficiently to customers’ requirements.

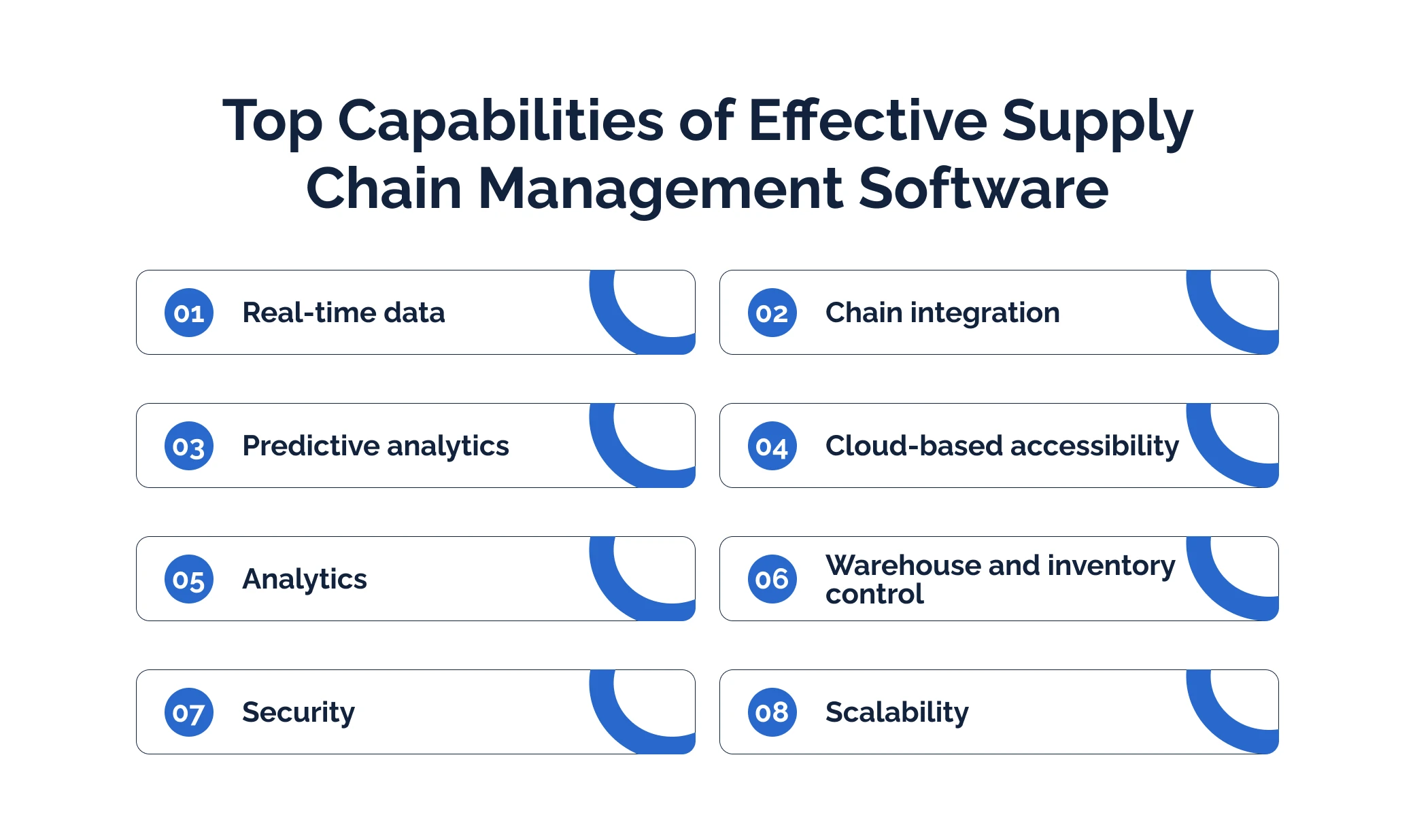

Top Capabilities of Effective Supply Chain Management Software

To truly be effective, a digital solution must incorporate supply chain management software features that address the demands of modern supply chain operations. These essential capabilities ensure smooth and responsive supply chain processes that adapt to the changing market landscape.

Real-time data

The software provides real-time data, allowing you to ensure secure processes and quickly respond to any query. You can control the shortage of missing products and manage any problems in manufacturing effectively. All stakeholders are independent and shouldn’t request access to crucial documents and updates. The SCM system allows them to save time and not depend on other employees. Collaboration is simplified.

Chain integration

The system helps to control all aspects of the supply chain among suppliers, distributors, customers, vendors, and others. If any issue in the supply chain arises, you have a strong network of information without connectivity problems. Using functionalities like email, help desks, and third-party tools, you can better plan supplies, prevent excess inventory or oversupply, and save costs without using separate management platforms.

Predictive analytics

Managers should always track the customer and market demands. So, the system provides them with insights into purchasing history to meet market conditions and customers’ expectations. For instance, if the customer preferences increase, you can increase production process speed. You can analyze the client’s current purchases and predict future demands, even for “what-if” scenarios. Based on product analytics, the manufacturers can identify inferior production on time. Factual data and advanced analytics given by the system help stakeholders handle challenging situations they may face.

Cloud-based accessibility

The software provides 24/7 online access to inventory level updates, status, and shipment management. Centralized supplier system management simplifies product coordination and allows suppliers to maintain more synchronized manufacturing tasks.

Analytics

Integrating advanced analytics streamlines aspects like self-service reporting, predictive modeling, performance dashboards, and data mining. You can check spending and contract compliance reports and set a pricing model based on market tendencies and analytics. Performance dashboards present key metrics for effective procurement and allow you to make better performance monitoring and decisive optimization.

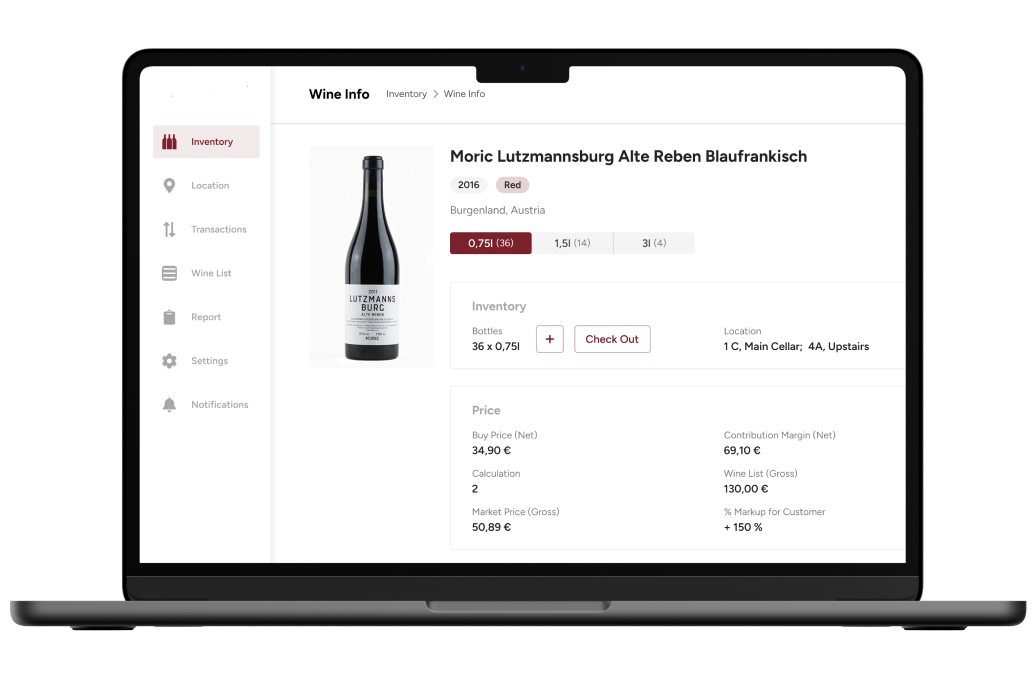

Warehouse and inventory control

With SCM, the managers get improved inventory visibility through real-time tracking across all levels of the supply chain. They can check the products in stock, their location, and the percentage of the inventory reserve. They can better plan and optimize the stock to match demand. Instead, they prevent costs from irrelevant excess inventory while optimizing stockouts. Automated barcode scanners, sensors, and IoT devices present automatic tracking of goods through receiving, allocation, and shipping. Such real-time access to data can detect and address any disruption in the supply chain on time.

Security

Security is, in fact, the heart of any business software. Security should be present to manage the software data. When choosing an efficient, secure software system, you should focus on how the data is encrypted and scan the software for viruses. Another point is to check the solution for reliable network monitoring and ensure the system adheres to the necessary technological standards to provide secure communications between all stakeholders, including customers and employees from different departments.

Scalability

Scalability is a critical feature for a business that potentially strives to grow, acquire a wider customer base, and integrate more supply chain solutions to handle customer expectations and demands properly. Importantly, for businesses that plan to scale, software must support multiple tools and apps without compromising the performance of the entire system and operations.

Benefits of Supply Chain Management Software for Business

If applying the SCM in a business in the appropriate context, you’ll get vast benefits, from better supply chain management efficiency to greater profits.

Simplified forecasting

Thanks to approved statistical tools with machine learning or the cloud-based solution, you can effectively carry out simulations and forecasts. Using these tools, you can analyze historical data to understand trends, seasonality, and other factors impacting demand and supply. Machine learning algorithms can give you high accuracy in handling large datasets and complex computations effectively. Since machine learning models and cloud computing improve their accuracy over time, the forecasting becomes more reliable, even with the scalability of your system.

Transportation control

In manufacturing, it’s critical to thoroughly manage all mobile operations related to production, such as planning, shipment, tracking, location, and carrier collaboration. A supply chain solution gives you transparent control over all transportation management processes, allowing you to properly use transportation costs and get current visibility of freight payments and auditing.

Cost-efficiency

We have already mentioned many points about the cost-effectiveness of SCM solutions, from in-time inventory control and reduced stockouts to accurate demand analysis through machine learning algorithms and reporting. With SCM, you can spend resources efficiently without shutting the business down. By defining current and potential losses on time, you can apply appropriate measures and improve the business operations requiring quality. The software’s cost-efficiency implies your chance to apply corrective measures based on data-driven insights and ensure seamless data flow, coordination, and decision-making across the company.

Future expenses control

Without SCM software, you can likely purchase costly inventory products while thinking they are in customer demand and can benefit your business. However, through software analytics, you can check if you properly allocate your costs and how you can reduce unnecessary inventory purchases and save expenses on critical production. Cutting off products that are not beneficial to the inventory process is one of many objectives of SCM software.

No data breaching and less risk

Without robust integration of digital supply chain management solutions, harming the business’s reputation is easy, resulting in customer loss. However, with a secure environment like SCM, all data is stored in a single space, allowing you to ensure the security and reliability of the entire supply chain process for your customers. The SCM creates automated data handling and transaction processes by integrating many supply chain processes into a single space, reducing employee errors.

Regulatory compliance

Compliance is surely a critical aspect of manufacturing since it reduces the risk of legal penalties and improves operational efficiency. SCM is also in charge of maintaining the necessary documentation and ensuring that all records are updated. It offers traceability features for managers to track production through the entire product chain, from checking product recalls and origin labeling to environmental standards. Among the features of supply chain management software are real-time capabilities that help businesses follow a wide range of regulations related to regulatory compliance, quality standards, safety and data security laws, and financial limitations.

Conclusion

A properly selected or developed supply chain software solution results in successfully controlled operations in diverse manufacturing sectors. To check the condition of your business’ supply chains, you should re-evaluate its infrastructure to see if it meets the demands and preferences of the customers. If your business objectives match the functionality and capabilities of the SCM solution, you can drive your business competitively, and by using advanced tech models, you can plan and regulate processes smarter. To ensure your company chooses the right software, we suggest you analyze if the software delivers at least those supply chain management software features and the benefits we mentioned.

FAQ

What is the objective of supply chain management (SCM) software?

The objective of Supply Chain Management (SCM) software is to help manufacturers optimize and control the overall efficiency of the supply chain process, from the procurement of raw materials to the shipment of the end product to the customers. SCM helps cover main business necessities like fast operations, quality inventory management, expense optimization, timely logistics, and distribution without risk issues.

By implementing an SCM solution, you get many tools and functions to control diverse departments within the supply chain, ensuring smooth collaboration between all stakeholders. You also get better analytics into inventory levels while controlling optimal stock levels corresponding to customers’ demand. All in all, all processes that are manually controlled without software are instantly automated and transparent within the supply chain management systems.

What features of supply chain management software improve supply chain performance?

To improve operational performance in the supply chain, the SCM software should incorporate features for boosting transparency, visibility, stakeholder collaboration, and real-time inventory management. The basic functions a successful SCM solution needs to have are the following: real-time stock control, advanced analytics for demands and inventory replenishment forecasting, tools for suppliers’ collaboration to monitor the delivery time, order placement, approval workflows, and more. Supply chain planning, order management, scalability, and compliance are other essential features you must consider while looking for software. Your overall purpose is to ensure proper demand predictions and resource availability through key metrics and data taken from software to enhance supply chain performance.

How to select and implement SCM software for your business?

You should thoroughly assess your business needs before selecting and implementing the right SCM software. This step depends on what features the SCM software should possess. Define the challenges you want to solve and the goals you want to cover through the software. Then, a budget is important to consider since different vendors set different pricing models depending on the functionality and competitive advantage of the software. Evaluate different software vendors and compare them regarding customer testimonials, market reputation, software features, industry expertise, and trial period. Consider the features mentioned in our article that a successful solution should have. If it can cover the basic requirements of your supply chain management aspect, you can get a potential return on your investment. Seamless integration of the software with your existing systems is also important to ensure interoperability of supply chain workflows between all stakeholders. Ask the partner if the software can scale with your business growth so you can adapt it to future changes in industry policies, customers’ preferences, and market tendencies. Finally, implementation, data migration, and testing performance are the next steps in our list. But this isn’t enough. After you implement a solution into business processes, to get stable work, you should regularly hold tests and improvements to get a positive performance review of key operations. Note that the steps we mentioned aren’t sufficient and can be modified. But they are good, so you can build on them and find the best solution for your business requirements.

Being experts in manufacturing software development through innovative tech solutions, Keenethics can help you start your search or develop a custom one based on your needs. We’ll consult you on key aspects, such as what determines the price and what makes the solution successful. Let’s start with a free consultation or project estimate.