The manufacturing industry is a field of constant and, to a great extent, ruthless competition between various firms. For this reason, manufacturing software development in this sector is so popular when it comes to asset management and asset tracking.

The goal of all firms in the modern markets is to gain the smallest amount of advantage and become better than other companies. In this regard, IoT in manufacturing is among the technologies that can have this positive type of impact. The main goal of this article is to look at the influence of IoT on smart factories and highlight how it’s essential for the collection of real-time data in various types of enterprises.

How IoT Influences Manufacturing

The influence of IoT solutions on the manufacturing sector is rather significant these days. IoT can perform several important roles in a manufacturing facility. Firstly, an IoT device is typically capable of playing a major role in automation and production planning. Many programmable controllers represent the initial form of IoT, which appeared back in the 1980s. Modern IoT is even more powerful. It’s, above all, capable of connecting various production machines to computers and the Internet, making their configuration a simple task for all stakeholders. Thus, IoT has a positive influence on manufacturing through, for example, various smart machines.

Secondly, IoT in manufacturing is likely to play one more role facilitated by current technologies. In this respect, it’s notable for its capability to collect information on various types of facilities and offer advanced statistics to the relevant stakeholders. For instance, you can install an IoT component into a machine that is commonly used by workers for producing this or that type of ware. This approach will, ultimately, allow you to optimize the production process through a focus on, for instance, improvements in the average practices of your workers. Connected devices can report how much certain individuals work and whether they are efficient at performing a certain type of job in your facility.

Three Places in Which IoT Has a Major Impact

Here are three main places in which IoT has a major impact, in our opinion. Let’s thoroughly review them to understand how you can apply this technology to your company:

1. Facility operations

In the paragraphs above, we’ve primarily concentrated on the facility operations. The main utility of IoT in such manufacturing processes is its ability to automate and analyze various production activities. On the one hand, you can use IoT to make certain activities in your business automatic. On the other hand, it’s also a great analytical platform. Combined, these approaches are likely to bring about higher operational efficiency for your firm.

2. Supply operations

IoT in manufacturing is also likely to have similar impacts within supply operations. Why is this the case? Supply operations can greatly benefit from IoT interventions because they also involve processes that can be either automated or monitored. Firstly, it’s possible to make some of the processes automatic and control them in real time through the use of IoT devices. Secondly, you can use an industrial IoT solution to monitor if certain aspects of the product delivery for your business fit the needs of production efficiency or not. In short, the benefits here are similar to those of traditional production processes. However, they’re extended to supply operations, which, while not directly involved in the production, nonetheless play a vital role in it.

3. Third-party operations

Lastly, a major positive role of IoT technologies also involves so-called third-party operations. These are operations performed by other companies. They typically involve connected products, such as raw materials. The main goal of IoT solutions for manufacturing here is to monitor the activities of the partners. For instance, you can use devices that will test the quality of the products they bring. With such quality analysis, it’ll be possible to understand whether further investments in some type of ware make sense or not. In short, the capabilities for improvements are extensive with this type of technology because it enables you to look into the activities of your partners apart from the activities that occur right within your company.

Key Benefits That IoT in Manufacturing Brings In

IoT in manufacturing brings in a tremendous number of benefits these days. Using it to promote informed decisions, you can maximize positive impacts for your business:

Improving efficiency

The first goal of using IoT devices in manufacturing is to improve efficiency. You can do this in two ways. In this regard, the primary way is to promote smart manufacturing by automating the majority of the processes in your firm. As for the second way, there’s also an opportunity to advance potent quality control through various monitoring tools. Ultimately, we believe that improved efficiency is the core benefit of IoT in manufacturing. Computer interfaces are potent enough to maximize many aspects of productivity for various types of firms.

Preventing downtime

Downtime is among the core threats for all types of manufacturing businesses. Why is this the case? Machines are constantly depreciating due to the rise of newer and more productive models on the market even if they’re not being used. Consequently, a core activity for any business is to prevent all types of downtime to minimize operational costs per machine unit. In this respect, IoT devices connected to cloud computing are among the strongest solutions to the presented problem. Why is this the case? Having a connection to the Internet or other connectivity devices, these tools can highlight moments when there’s unwanted downtime in production. This is essential for preventing situations in which a machine would stay inactive without maintenance for several days. Few devices are as potent at optimizing operational costs as modern IoT in manufacturing.

Promoting a small-scale improvement paradigm

IoT devices allow one to see major and minor problems within their production processes. Using this information, it’s possible to transform many aspects of productivity in your business. For example, you can review product cycle time and speed it up through new methods. Smart sensors can also identify moments of problematic equipment failure. This means that IoT in manufacturing is the perfect framework for small 1% improvements in your everyday processes. With this technology, you can strive toward perfection through daily upgrades in your production processes.

Upgrading safety

Manufacturing companies feature an upgraded level of safety after they implement IoT on the average manufacturing floor. Why is this the case? The reason is rather simple: IoT devices enable you to monitor potential problems with the production devices and, more importantly, with various processes surrounding them. This means that it’s possible to minimize potential pitfalls in production and ensure that your workers function in a safe and friendly environment. Implementation of IoT in the manufacturing industry is among the core safety technologies because this type of innovation can detect and prevent situations in which workers are endangered.

Reducing costs

IoT in manufacturing is also a perfect way to reduce all types of costs. How exactly does this technology achieve its goal? Above all, it enables you to review small-scale changes in production. For example, it’s possible to use this technology to minimize equipment failure by making maintenance smart. More importantly, you get an opportunity to optimize your processes through automation or some changes to the way they’re done. Real-time monitoring is a perfect technology for understanding whether some of your processes are optimal or not because it collects information throughout all production periods rather than at the moments when workers would be willing to showcase their best effort.

Improving scalability

The core problem with scaling all types of business lies in the cost of labor. It’s often too costly to hire more individuals for a firm to expand because you need too much equipment for them. IoT solutions in manufacturing solve this problem once and for all. They achieve their goal in two ways. On the one hand, these technologies improve the production cycle through all types of automation.

On the other hand, they are also notable for promoting productivity improvements of all types. What do we mean by that? You can use IoT in manufacturing to, for example, find inefficient processes and then retrain workers to make them much more efficient. In short, the scope of possibilities with this technology is wide. You can genuinely promote a large number of improvements through it, which will allow you to expand the input of a firm and, at the same time, do this with minimal expansion of the workforce.

IoT Adoption Challenges

IoT involves multiple adoption challenges that occur due to the essential characteristics of this technology. Let’s review them in depth:

1. Ensuring data safety

The first challenge that you’re likely to encounter is undoubtedly data safety. IoT enables you to engage in remote operations. Regrettably, this means that this tech, just like every other wireless technology, is notable for hacking risks. Since you’re exposing your technology to the Internet, there’s always a possibility that someone will break into your network. The data leaks can vary in terms of severity. In some cases, there’s a possibility of leaking information about the new production processes. In other situations, there’s a risk of changes to the production values of your machines that can disrupt their long-term functioning. Fighting against potential hacking is among the key challenges of IoT implementation in manufacturing.

2. Establishing training needs

IoT technology is quite difficult to implement in the majority of cases. Many of the configurations offered by smart machines may require long-term training. While such training within production organizations is relatively easy to achieve, it may be highly problematic in situations where you also need to work with supply chain management organizations. They’re likely to have their own set of employees, who may either be too difficult to reach or, for instance, too numerous. This problem is especially acute in situations where you have to work with numerous suppliers. Training all those individuals to work with your systems is difficult and, in many instances, almost impossible.

3. Promoting integration

It’s not enough to use IoT devices in your business. You also have to integrate them into the core processes properly to reap the cost savings benefits. In this regard, a core concern lies in the fact that many companies are investing in IoT without thinking about ways to integrate it. For instance, some firms buy new types of production machines but then fail to upgrade the entire manufacturing process to fit them. This issue ultimately results in the inability to maximize the impacts of IoT solutions in manufacturing. To use these technologies properly, you have to focus on the training of the workers and the integration of other production machines in your firm. Only this approach can guarantee that you’ll be able to get maximal benefits from the integration of various IoT devices. Otherwise, integration problems will prevent you from making any other types of improvements.

Advanced IoT Use Cases

Here are several advanced Internet of Things (IoT) integration approaches that will likely have a positive impact on the majority of firms that know how to integrate them into the production process.

Doing remote review

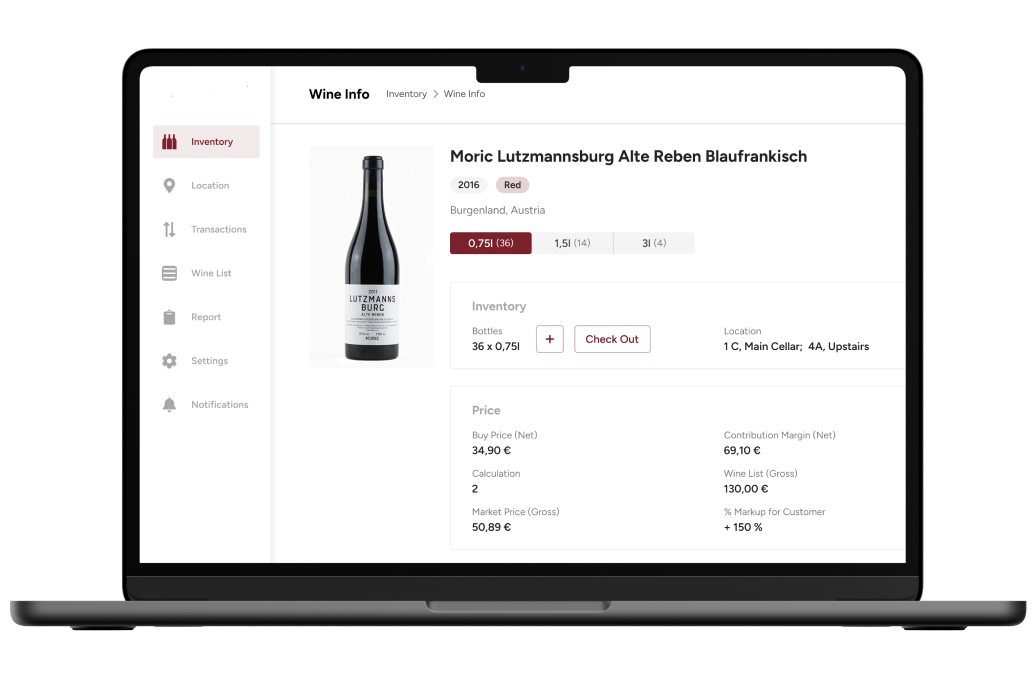

Above all, you can use IoT to remotely review the work of certain machines. For example, it’s possible to learn their status and operation capacity. In some cases, even productivity levels are available. This is essential for cases in which you want to, for instance, create a lights-out factory. An IoT device can report your inventory level and, later, enable you to make high-quality decisions on filling up all types of inventories. In short, it’s possible to create factories that are fully remote with the help of the presented technology.

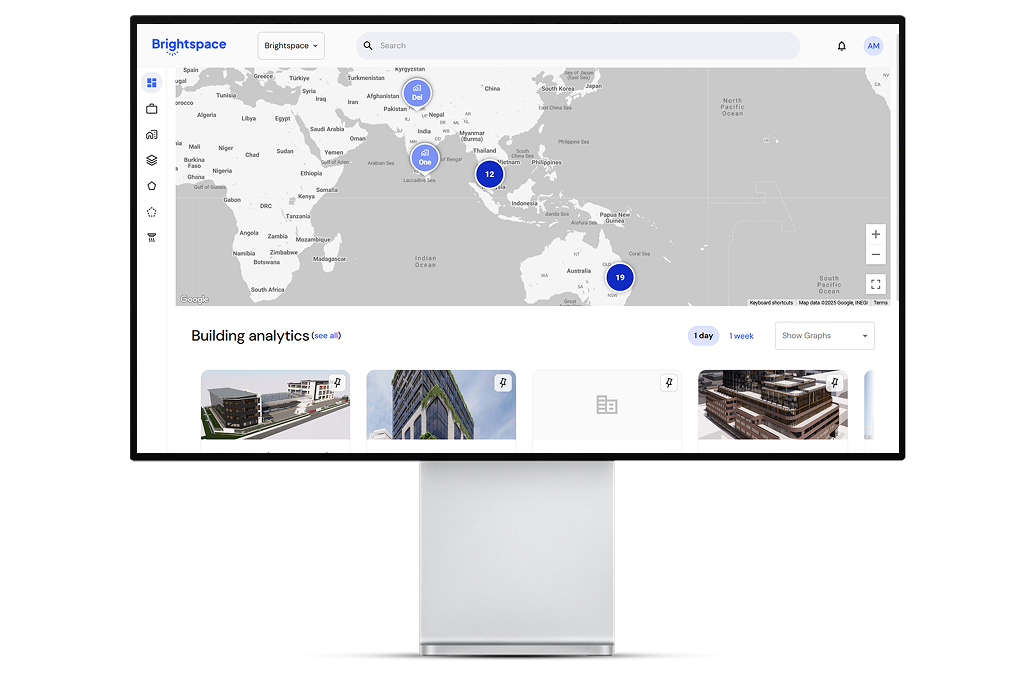

Using digital twins

A digital twin is a digital copy of your physical production systems. For instance, you can have a digital twin of your factory, which can be used for all types of information analysis. Such systems enable you to see if one can increase the productive capacities of a facility by increasing the number of its workers or changing equipment to one with different production capacities. For individual machines, this technology is a perfect way to review potential reasons for operational breakdowns. In short, it offers many capacities to the average decision-maker these days.

Improving logistics

Logistics is a process that involves numerous small activities. Consequently, the best way to improve logistics is to guarantee high-quality tracking for all types of actions. Why is this the case? Regrettably, logistics involves the inevitable loss of some goods due to inefficient processes. The Internet of Things is capable of improving tracking for these assets. As a result, the probability of losing some type of ware becomes much lower with the use of these technologies. IoT is among the best ways to upgrade tracking in modern industries.

Promoting KPI-based improvements

In our opinion, KPIs are one of the best models for tracking the productivity of particular workers and even whole departments. What’s the problem with this model? KPIs are typically very difficult to track. As economists say, we face the concern of information quality: it’s challenging to find high-quality information that can be genuinely transformative. In this respect, the Internet of Things is a direct pathway to so-called Big Data. It enables modern firms to collect more information about various production processes than ever before through a set of applications. This service, in turn, is ideal for the goals of delivering better KPIs for a firm. The more data you have, the easier it is to create good production capabilities in your company.

Key IoT Trends in Manufacturing

IoT for manufacturing promotes multiple core trends. Let’s look at the core insights concerning their application:

Improving worker safety

IoT devices can improve worker safety in multiple ways. Firstly, IoT is often used to create limits for certain machines. For instance, they may have detectors that prevent humans from being hurt during production. Secondly, IoT can track workers and offer sets of recommendations for improving their practices in various cases. Lastly, IoT devices have warning systems that showcase when certain machines are reaching the peak of exhaustion. Using this information, it’s possible to understand whether a certain brand of machine is currently dangerous or not.

Working on security

Security of information is one more important trend in modern manufacturing. In this respect, various firms are making large-scale investments into changing diverging aspects of production. For instance, some corporations are investing in improvements regarding encryption. Others focus on employee training to ensure that no leaks of information occur from within various firms. All in all, we’re seeing a wave of investments aimed at making the Internet of Things as safe as possible for the majority of users.

Promoting Machine-to-Machine (M2M) communication-based automation

Machine-to-machine (M2M) communication-based automation is one more trend that is likely to become dominant in the upcoming years. What do we mean by M2M automation? It’s the process of interconnecting machines into one network that is governed by humans or even AI. In short, it’s now possible to use connectivity to create machines that communicate between themselves and then organize production according to this type of communication. We believe that this technology is one more step towards the promotion of full-scale automation in the manufacturing field.

Advancing VR and AR integration

Lastly, a positive approach is to use AR and VR integration into IoT. IoT devices are perfect for this technology because they can display a lot of information about certain machines. As a result, you can use the data from IoT to then display it in AR or VR spaces. Using such approaches, engineers of various kinds can quickly scan whole production rooms and make long-term judgments on their efficiency. Right now, VR/AR technology is not yet there in terms of productivity and battery efficiency. Nonetheless, workers in the future may be using a combination of AR and VR with IoT to obtain high-quality information during the production process.

Summary

To summarize, the use of IoT technology in manufacturing is highly beneficial for the majority of stakeholders. It can improve worker safety, automate productivity, and upgrade performance per employee. In this regard, all those benefits stem from the ability of the technology to make independent decisions and, more importantly, collect tremendous amounts of information. Consequently, we believe that it’ll gain popularity in the upcoming years among the majority of the firms on the market.

FAQ

What are the uses of IoT in manufacturing?

It can be used to automate certain processes and, for example, upgrade data collection.

What IoT devices in manufacturing exist?

In our opinion, the most common types of IoT are normal production devices with computing units inserted into them. For instance, it can be a sensor with some form of a small-scale computer attached to it.

What future will IoT in manufacturing have?

We’ll see a further expansion of this technology in manufacturing. The reason for this is simple: there’s a never-ending race towards improved productivity in the sector, with which IoT greatly assists.

What steps are necessary for implementing industrial IoT?

You need to choose what type of device you require and why. Then, it’s essential to train employees in the implementation of these devices to ensure that they efficiently use them. Lastly, a good option is to also focus on the installation of appropriate infrastructure to facilitate the maximal utility of the new technologies. After doing all these steps, you can install the devices in your firm and reap the benefits of their usage.

In this case, Keenethics is a perfect development partner!