Today, the question in the manufacturing business is whether to adhere to effective traditional, proven methods and machinery or try digital tools that can reduce human efforts and continue to become time-tested. The world is moving forward. And in practice, we see that if you stand still, it will be difficult to outperform competitors in business. Therefore, business owners who analyze and think strategically about tomorrow’s production chain are often ready to implement new software solutions to review the quality of their services, retain old clients, and attract new ones. Indeed, what to choose is a matter of time.

In this article, we’ll define the revolutionary way to change efficiency, precision, and innovation in the manufacturing sector. The success of your business depends on your readiness and capability to adapt to digitalization. We’ll explain why modernizing manufacturing is vital, delve into 15 different types of manufacturing software, and discuss key features to consider in the manufacturing system. We hope that by the end of the article, you’ll get a clear picture of what is and isn’t best for your business.

Defining the Concept of Manufacturing Software

Manufacturing software is a digital system that allows manufacturing business owners to plan, control, and execute tasks effectively while lowering wasteful operations. Financial accounting, sales, production scheduling, supply chain logistics, and human resources can all be managed in one place in a specific manufacturing software system. Depending on the business needs, there are different manufacturing software types, which we’ll cover in the other sections.

Many production processes can be automated if the manufacturing software is chosen specifically for business needs and implemented efficiently. By integrating digital manufacturing software, manufacturers can improve quality control, maintenance, inventory, and supply chain operations. When owners get real-time data analytics, they know where to move and make the best decisions to meet market demands and challenges.

Regardless of the size of your business and the complexity of your business operations, you should make a relevant choice on the right manufacturing system. When you align with the right development manufacturing company, your investments can address specific industry needs, making your business more profitable.

The Role of Software in Modern Manufacturing

Today, almost every sphere has been shifted through advanced technologies, and we’ve been assured about their relevancy and efficiency.

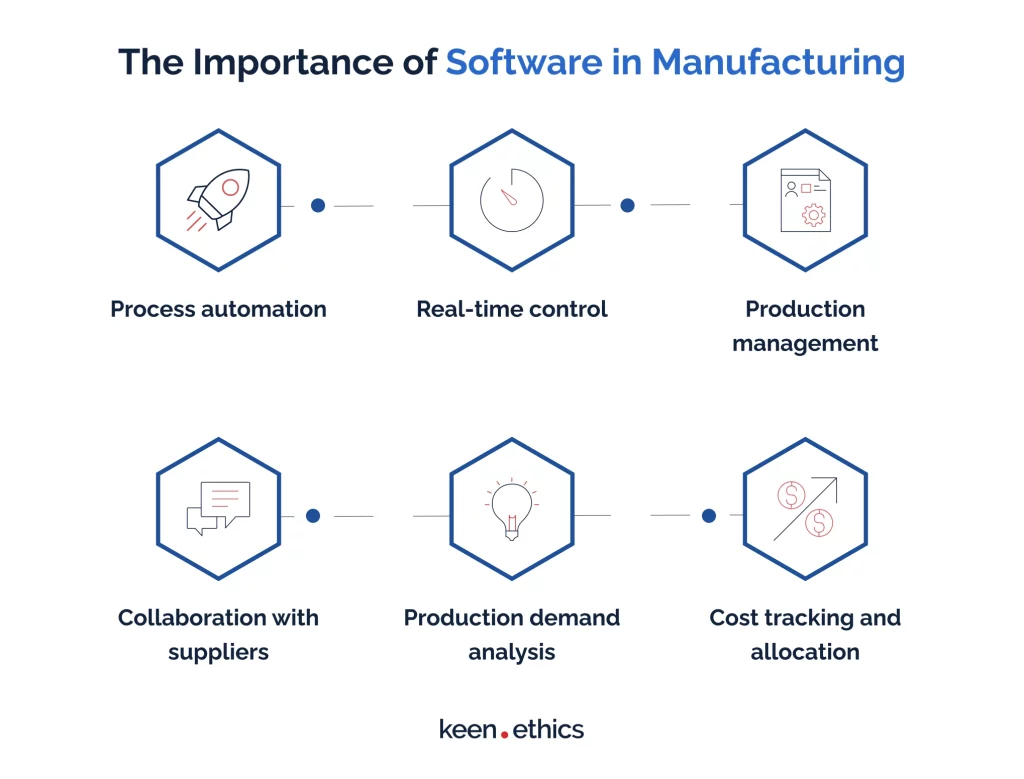

Let’s grasp the importance of manufacturing software in the industry.

Process automation

Years ago, manufacturers were accustomed to repetitive operations, from inventory management to production scheduling, and traditionally, they managed business processes manually. Operations like tracking and changing orders, inventory management, and controlling equipment were complex and open to errors because of inaccurate actions or overworked employees. Now, business owners have access to cloud-based solutions to reduce labor costs and potential errors. Moreover, these systems are centralized, ensuring all specialists can access the same resources while reducing misunderstandings.

It isn’t a simple trend or temporary shift but an important strategic need. Without integrating manufacturing software, a manufacturer may face inconsistency in servicing customers. These solutions can offer employees instant access to needed information and analytics to enhance planning and strategies and increase production efficiency across different departments, from accounting and management to sales and customer service.

Real-time control

With manufacturing software, the owners can track every aspect of production from a centralized dashboard. The operators and managers get instant status updates on their orders, managing them in ‘progress,’ ‘done,’ or ‘delayed.’ Accordingly, they can make quick decisions and address any issues or delays. Also, the software helps to allocate the resources properly, including reducing downtime of the machine, which is underutilized. The managers can set the machine for another task, increasing production performance. The final and not least important benefit refers to security and quality. The owners can track if the product doesn’t meet quality standards and prevent defective products from delivering them to their clients.

Production management

Inventory management is critical since surplus stock constrains budgets and insufficient production delays delivery. Enterprise Resource Planning (ERP) systems optimize control and management by allowing managers to track the movement of materials and maintain accurate inventory levels while managing overstocking or understocking.

Collaboration with suppliers

The software helps to provide a smooth supply chain, streamlining operations in several ways. It is transparent, allowing suppliers to access real-time information on production schedules and order statuses. ERP systems can automate ordering, guaranteeing a steady supply of materials.

Production demand analysis

Suppliers can analyze purchasing data through the system to forecast production demand for specific periods. This helps them accurately analyze demand levels and properly decide production schedules. Even if demand fluctuates, manufacturers can ensure the relevant production level and provide the materials for ‘what-if’ scenarios. This means the manufacturers can avoid overstocking and understocking, reducing unnecessary costs and improving profit flow. ERP systems offer visibility over production and inventory across different locations for businesses with multiple warehouses.

Cost tracking and allocation

Manufacturing systems provide tools for thorough financial management. Manufacturers can see which products and production processes require resource allocation and use key metrics to align their financial goals with actual production performance.

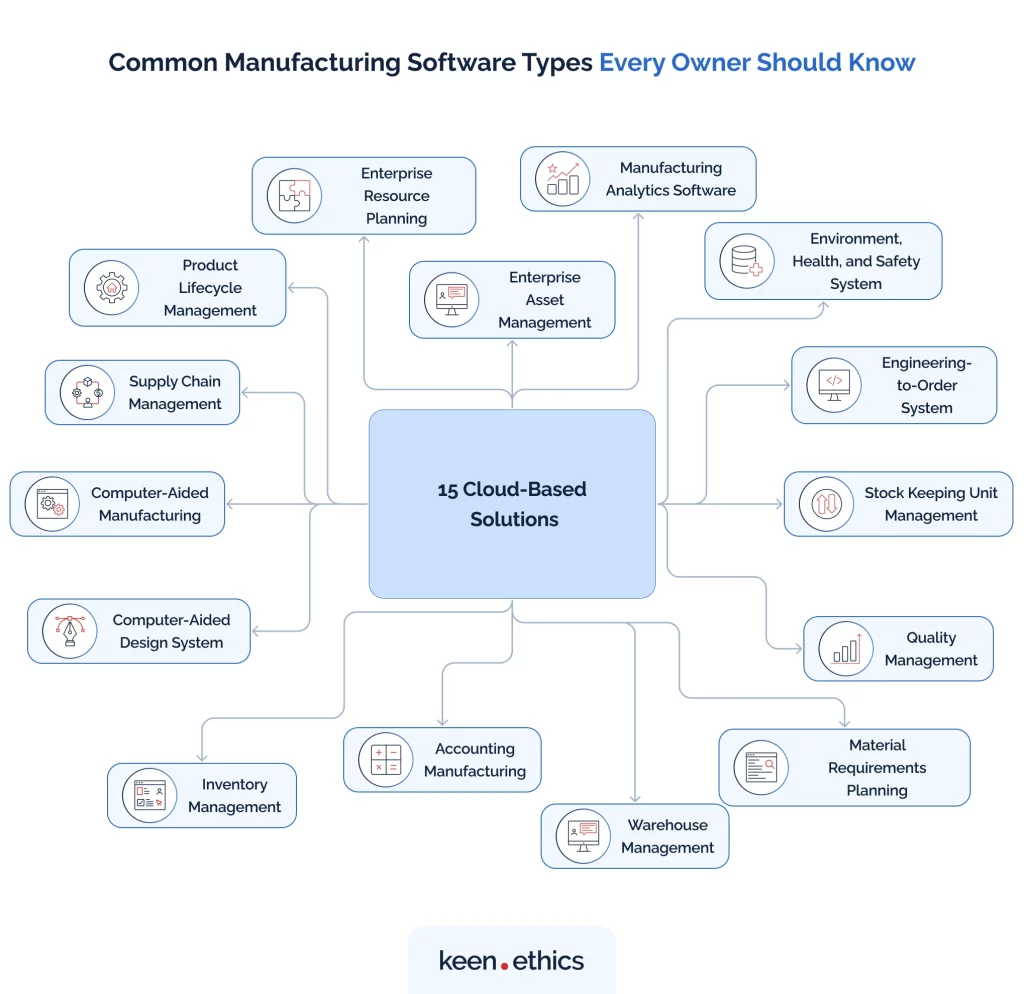

The List of Common Manufacturing Software Types Every Owner Should Know

Cloud-based manufacturing software is a key solution to consider to remain competitive, simplify processes, and allocate resources where possible. The question is which solution to start from since many manufacturing solutions offer capabilities for diverse needs. Another question concerns the vendor’s license models, unique offers, and deployment methods. Is there an ideal system that may work perfectly for your business?

Let’s examine.

Enterprise Resource Planning (ERP) software

Enterprise resource planning (ERP) systems are the core systems in the manufacturing industry, uniting critical data in one location. The employees can easily access any data without getting lost among data silos which are complex to navigate. Now, making decisions is easier and more efficient with ERP software. These systems help to control almost all aspects of the manufacturing process, from purchasing the material to inventory management, control, and delivery. Planning all operations is simplified since manufacturers can use a single platform to integrate and control all processes. This reduces risks, errors, and possible inconsistencies.

Product Lifecycle Management (PLM) Software

Product lifecycle management (PLM) software offers a comprehensive view of product data from initial requirements to change orders. It allows the manufacturer to improve production quality by managing the entire product lifecycle. The system centralizes all critical data, allowing teams to collaborate easily and track all documentation. It incorporates key data like product information, documentation, requirements, required changes, and workflows. So, managing documentation, viewing real-time changes, and ensuring regulatory compliance is far easier.

Supply Chain Management (SCM) Software

Supply chain management software operates the entire supply chain, involving different movements and storage of raw materials, work in progress, and customer consumption. The final aim is to satisfy the customer’s business requirements through a qualified final product. A supply chain management system controls outside interactions with suppliers, warehouses, distributors, and end customers, including coordinating the entire flow of products. This solution helps manufacturers detect supply chain issues and forecast supply and customer demand to optimize delivery schedules and planning.

Computer-Aided Manufacturing (CAM) Software

Computer-aided manufacturing (CAM) software offers computer-controlled machinery to automate manual processes. CAM software helps to convert CAD designs into instructions for machines to follow. It allows businesses to automate many processes and increase efficiency and quality.

Take a recent example: imagine manufacturers creating furniture. The engineers start by designing the part of the product in computer-aided design (CAD) and creating a 3D model, which they then send to computer-aided engineering (CAE) software. CAE software checks this model through many simulations to simulate its performance and ensure it meets durability standards and safety. When the design is ready, computer-aided software generates machine instructions for the CNC machine. In parallel, the team controls the process through collaborations and iterations with other members to maintain an efficient workflow from concept to production.

So, CAM is a comprehensive technology that unites many types of manufacturing software to bring an idea to life. The main objective of computer-aided software is to provide a faster production process and more precise components using only the required amount of material and resources. In some cases, it’s even more efficient since it can reduce energy consumption.

Computer-Aided Design (CAD) Software

Computer-aided design (CAD) software is designed for engineers, drafters, and artists to help them create accurate drawings and illustrations. The software helps create 2D or 3D models and allows designers to analyze and assess every minor aspect of product design. Depending on the level of detail and depth for manufacturing product design, the users can use different types of CAD systems, from 2D CAD to 3D solid modeling. The role of CAD lies in its ability to create detailed and precise designs for any product, minimizing the efforts of designers for manual work. The best about this software is that manufacturers can modify, improve, and iterate their designs easily without creating them again from scratch. The ready-made design can then be used for prototyping, which manufacturers can test and evaluate before the product goes into full-scale production. It’s a cost-efficient solution for manufacturers.

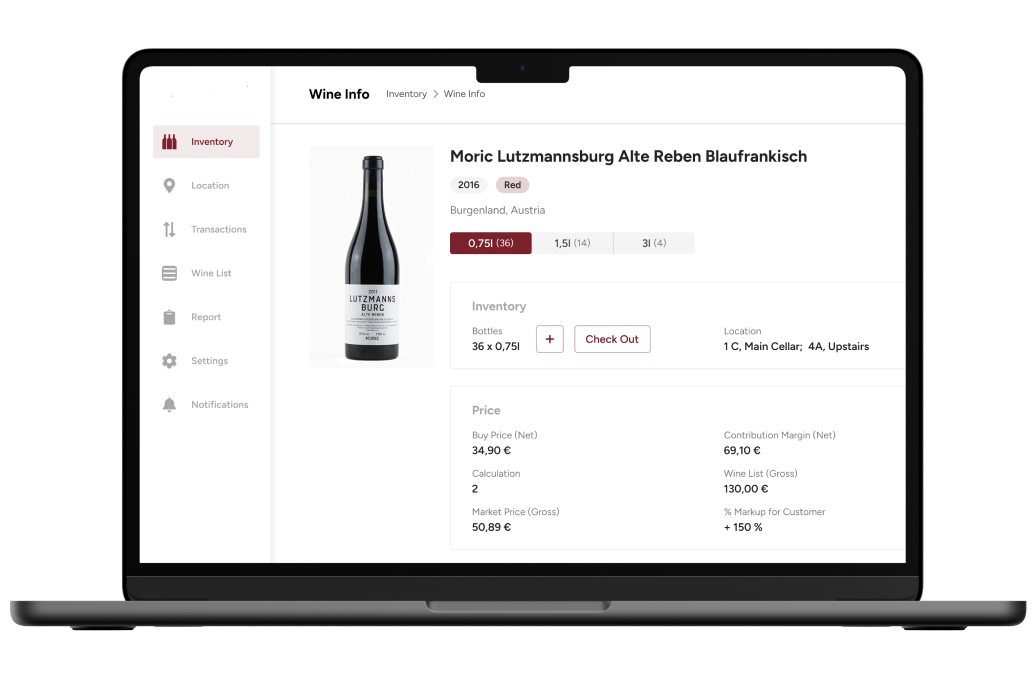

Inventory Management Software (IMS)

Inventory management is a huge, complex process involving many critical manufacturing operations in the production chain. Inventory management software (IMS) tracks inventory, controls inventory levels, and manages orders, sales, reports, and more. Many processes become automated thanks to the software’s optimal stock amount counting and periodic updates. The software controls the stock running, reordering process, and demand planning to provide smooth customer operations.

Inventory management can be challenging, with issues such as wrong inventory planning, over- and understocking, and a disorganized warehouse. However, this type of software can help prevent these issues if implemented and used properly. Proper production calculation is always critical for proper functioning and resource optimization. Supply disruptions can lead to the challenges mentioned above. If not addressed, you may face delays, customer nonfulfillments, and, at the very least, customer loss.

Accounting Manufacturing Software (AMS)

Accounting software for manufacturing helps manufacturing owners manage accounting processes like accounts payable, ledger, payroll, financial reporting, bank reconciliation, and expense tracking. This software can refer to some of the enterprise resource planning software mentioned earlier. Accounting software in manufacturing allows for managing finances in real time without waiting until the end of the month to get accurate reporting. It provides easy access to all information and reduces any manual work. In comparison to traditional ways like Excel spreadsheets, you get the maximum outcomes when using the software.

Warehouse Management System (WMS) Software

Warehouse management system (WMS) software controls daily warehouse operations from when the production enters manufacturing to when it leaves. Controlling the supply chain activities is its key objective. Manufacturers have real-time visibility of the inventory in transit and warehouses – shortly, all is about inventory management. A good WMS system allows manufacturers to handle activities from one interface, from receiving, picking, packing, shipping, and replenishment. As a result, manufacturers can minimize errors in product transportation or duplicating some orders.

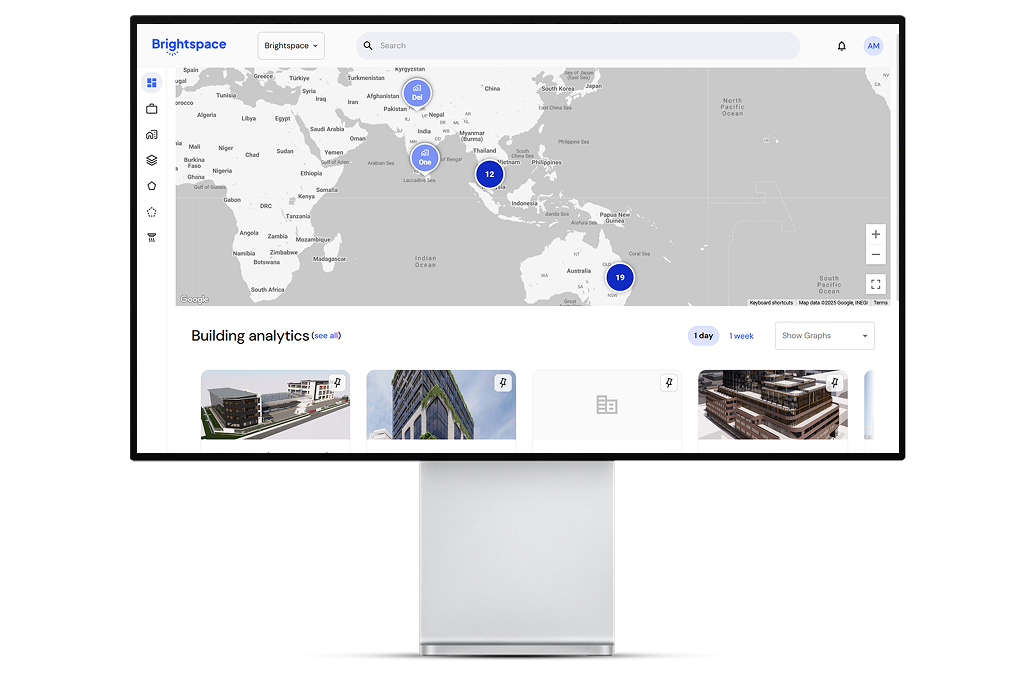

Enterprise Asset Management (EAM) Software

Enterprise asset management (EAM) is software that manages the operational efficiency of assets and equipment. Its objective is to optimize quality, productive uptime, and operational expenses. AI analyzes data from EAM software to help maintenance teams make better-informed decisions through preventive measures and investments in physical assets. With the EAM software, manufacturers can optimize operational assets and equipment control throughout the entire lifecycle – from acquisition to disposal. Assets can be of different shapes and sizes, from pipelines, transportation fleets, machinery and equipment, tools and fixtures used by employees and vehicles to IT hardware and buildings, including warehouses. Using sensors and IoT devices, EAM helps monitor the condition and performance of all these and other assets. It collects data on related parameters like maintenance schedules, temperature, performance metrics, vibration, and more.

Manufacturing Analytics Software

Manufacturing analytics software collects circular data from many different sources, such as people, other software, and machines, to present what happens on the manufacturing floor and improve processes, if any. This purpose-built software replaces all traditional, outdated ways to manually check the machines from the top down. Instead, manufacturers can use one single point with the data to monitor several machines, equipment, or parts of machines, measure performance, and improve it.

Environment, Health, and Safety System (EHS) Software

Environment, Health, and Safety (EHS) software provides manufacturers with valuable strategies and measures for minimizing risks and hazards in the workplace environment and communities. The software tools allow them to track, report, and improve performance, ensuring that the business adheres to legal standards and maintains safe conditions for employees, customers, and the environment. The software has a wide functionality, helping companies comply with EHS regulations and track safety-related procedures.

Engineering-to-Order System (ETO) Software

Engineering to-order (ETO) software helps manufacturers be agile, capitalizing on good product conditions and minimizing costs when demand slows down. Businesses sometimes have pressure on tight deadlines and fixed budgets. So, the crucial part for them is to have a properly defined bill of material at the beginning of the project and a well-defined cost for the production without changes throughout the manufacturing cycle. ETO software allows manufacturers to support processes like resource planning, product design, resource allocation, and customer interactions. Using the software, the manufacturers can track and assess daily operations, including expenses, labor, product configuration, warranties, returns, unique orders, long lead times, changes in production, and more.

Stock Keeping Unit Management (SKU) Software

Stock keeping unit software is used in inventory management, ensuring that any product your business receives is properly tracked and assessed. Wherever the manufacturer stores their products, the software provides a clear picture of stock availability. The software is critical for conducting stocktakes to record how much stock your business holds in the warehouse or storage rooms to match the stock levels recorded in the inventory management system. This directly affects profit margins and helps to make strategic product decisions for business revenues and growth.

Quality Management System (QMS) Software

Quality management systems (QMS) software is also valuable in manufacturing. It simplifies the process of quality inventory control, manages non-conformances, and ensures production adheres to all norms and standards. With quality control software, business owners can efficiently create and track documentation, conduct internal audits, and analyze quality assurance if it’s compliance-related.

Material Requirements Planning (MRP) Software

Material requirements planning software (MRP) aims to control the supply chain and ensure the availability of the right material at the right time for product production. The software helps to manage inventory levels and set product forecasts for future demand. It can also track and count the average lead time required to receive the materials from suppliers and take orders to manufacture the product. Based on the following data, the software forms the production schedule and forecasts the quantity of materials for this schedule. It minimizes costs by defining the amount of unused or slow-moving inventory.

Although it may seem that these manufacturing software types are similar in their functionality, they have unique features that cover customers’ diverse needs and purposes. So, if you have a specific vision of your idea but can’t decide which type of software it refers to, you can consult with us, and we’ll offer you unique values for your project.

Major Features of Manufacturing Software Tools

Now, you know the common manufacturing software types. Considering the fact they all differ, there is one thing uniting them. This is a FEATURE of the software. Let’s define the must-have features of all types that are critical to include when developing your own software or integrating the existing software into your manufacturing processes. We’ve compiled a list of the must-have and most practical features so you know what to consider when buying software, developing your product, or updating your existing one. If manufacturing software is your first startup idea, these features are for you to consider. Also, if you want to update your existing solution, please assess if your product incorporates them. They are critical and should be present in a successful manufacturing software platform.

Centralized digital repository

This aspect is paramount for the company. A centralized repository facilitates employees’ working processes, allowing them to access needed data quickly. It improves internal communication inside the company, and through brainstorming sessions, employees can share insights on decision-making or suggest new ideas.

Comprehensive tracking

Centralized platforms should be transparent and provide bidirectional visibility across the supply chain. By providing manufacturers with real-time data about inventory stock levels and order demand, employees can properly control the levels of finished products and raw materials and support quick replenishment. Performance tracking reports and key performance indicators will help you gain insights and implement needed improvements for your production functioning and profits.

Demand forecasting based on historical purchasing data

When the software stores information about production sales, the manufacturers can better predict the inventory demand for the next period. It can better meet the business targets and align with potential demand fluctuations.

Manufacturing accounting

Manufacturing accounting software is crucial for integrating diverse accounting processes and allowing for relevant tracking of the financial aspects of manufacturing businesses. Manufacturers have better financial visibility and can see areas for cost reduction or efficiency improvements. Intuitive dashboards with key financial metrics, reports, transaction management, and alerts are all the core components behind manufacturing accounting.

Traceability

Traceability is key for tracking the location of your production, its delivery, and quality, allowing the recall of faulty products if needed. The effective traceability system should offer visibility of core items like product numbers, batches, and expiration dates so manufacturers can take measures when needed.

Equipment maintenance

Equipment maintenance gives manufacturers a clear picture of whether the equipment is in optimal working condition to accomplish work reliably. Such software allows for electronic tracking of equipment usage and application preventative measures. It can automatically define conditions requiring maintenance. The main benefit is that the equipment maintenance software ensures that manufacturing equipment is certified for use, which is important to sustain competitive services in the manufacturing industry.

How to Identify the Best Manufacturing Software Development Partner

When choosing a company for manufacturing software development, it’s crucial to recognize that their success is intertwined with your efforts. While a professional company can certainly develop a digital project, it’s essential that they first grasp your objectives, requirements, and vision to deliver a solution that truly aligns with your needs.

1. The foundation of a successful partnership lies in forming the initial requirements, including business drivers and goals from your side. In this case, they can only properly define a clear direction for future development tasks. When having well-defined requirements, you can assess if the company understands them and has the expertise to meet them.

2. Determine the features you want to see in your software and assert what goals these features should complete. Critical aspects like integration with other systems, inventory management, production scheduling, and cost reduction – are the aspects you may want to review in your production. Here, you may consider some technical specifications for your project, like integration with other tools or preferences for tech stack.

3. Audit your system and set questions related to what you want to improve. What specific problems do you have in your manufacturing system?

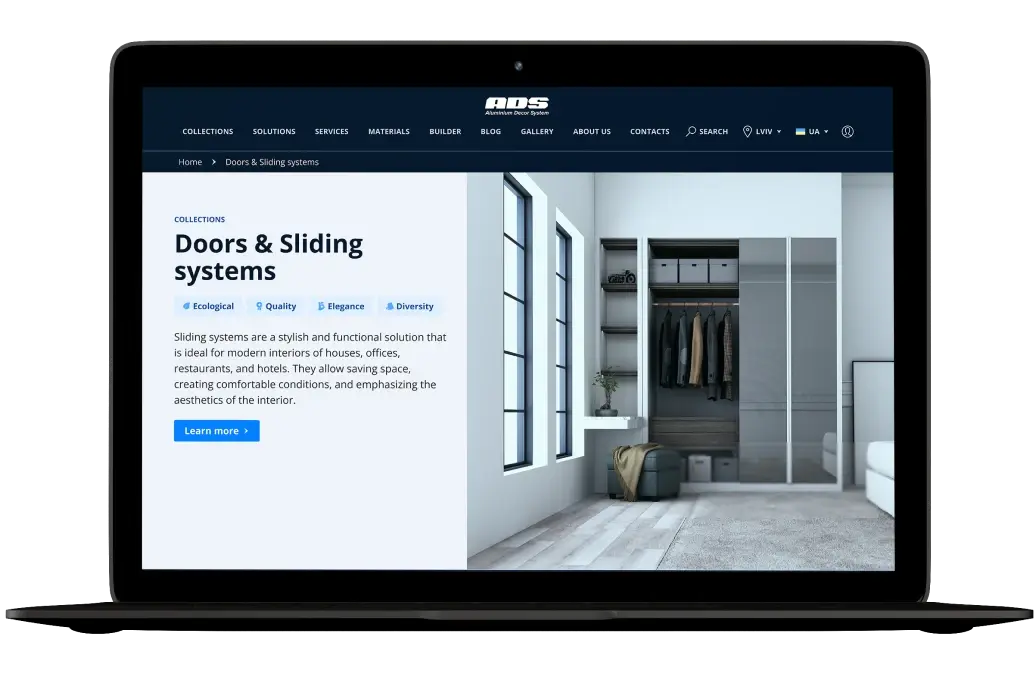

4. Check their experience in manufacturing. Expertise in web development is good. However, it’s more valuable if they have a portfolio in manufacturing since they can be more aware of the challenges and nuances behind the development of manufacturing products.

Finding the right manufacturing software development company is critical to ensuring product success. The process implies not only evaluating potential partners’ technical capabilities but also ensuring you specify and voice your specific needs and goals appropriately. By clearly defining your requirements, assessing the company’s expertise in the industry, and ensuring they can integrate with your existing systems, you have all the chances to start an effective partnership.

FAQs

What is the most effective software for manufacturing?

Firstly, recommending any specific software to you is subjective since the choice depends on your business’s needs and vision of a particular product. Secondly, keep in mind that developing software from scratch is one thing, but implementing a ready-made solution is another. We can offer different options for each scenario, with each solution having pros and cons.

Therefore, we recommend exploring manufacturing software tools yourself or contacting Keenethics for a free consultation. We will listen to your requirements and offer you a cost estimating software that will definitely benefit you.

What are the benefits of implementing manufacturing software in my business?

Manufacturing software can help you better optimize your processes through automation. You save capital on repetitive and odd manual tasks and spend it efficiently on improving inventory management and strengthening quality control. You get better real-time monitoring, fewer human errors, predictive maintenance, and efficient resource allocation. By implementing the right solution or developing software from the ground up for your customers, you can allow business owners to reduce downtime and provide them with better data visibility and decision-making, ultimately improving their business’s productivity, profitability, and market competitiveness.

ERP vs. MRP: how do they differ?

ERP software includes comprehensive systems that offer functionality and centralize all aspects of a business. Sometimes, ERP software can incorporate an MRP module or functionality. Conversely, MRP software is designed to improve manufacturing processes, especially production planning and scheduling.

We offer top-notch capabilities to help our clients keep pace with market trends and customers’ demands. Consult Keenethics for a free consultation and let your business transform.