The manufacturing industry is grappling with a significant challenge: a shortage of skilled personnel and a widening skill gap in specific domains. According to Ernst & Young Global Limited, if this skill gap is not addressed, about 2.1 million jobs in the manufacturing sector could remain unfilled by 2030. So, companies must provide their employees with the right tools for reskilling and upskilling.

In this article, we’ll define the benefits LMS solutions can bring to manufacturing businesses. Also, we’ll present tips for finding or developing the right LMS you can use to reskill and upskill your workforce effectively.

Why Is LMS Important for the Manufacturing Industry?

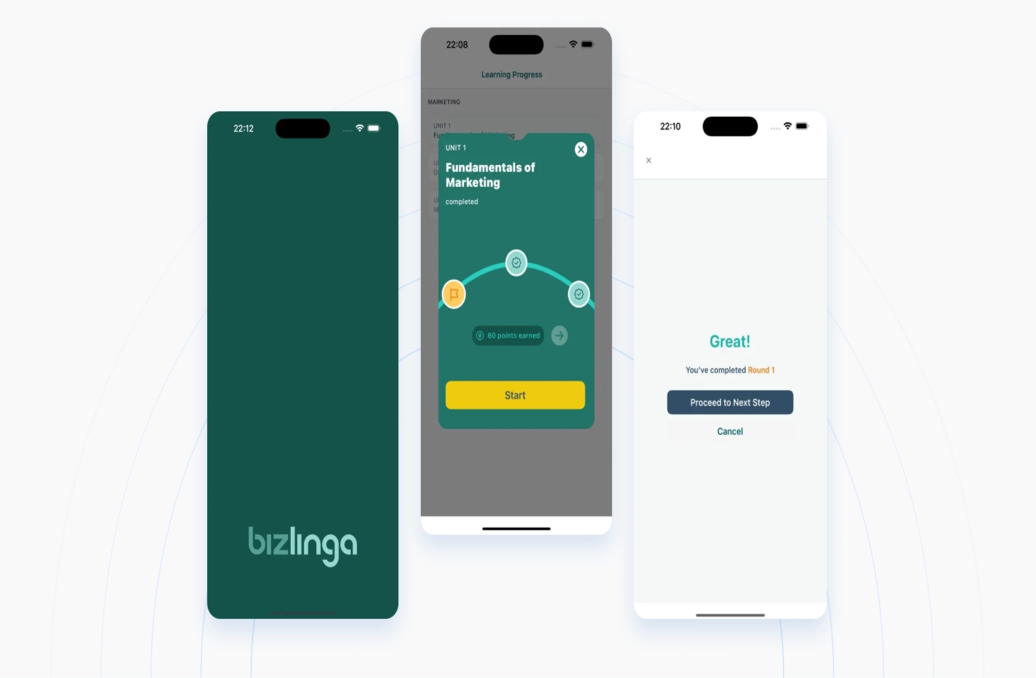

Today, businesses are developing and try keeping pace with technologies and competitive markets. Many companies have already weaned from how, just recently, the employees attended mandatory hours meetings and went on business trips to gain new experience and develop skills. We are not speaking about training effectiveness now but about the fact itself. Today, many have switched to flexible online training solutions that allow them to combine work and personal time and improve performance in diverse aspects with minimal effort, resources, and time waste.

What is the role of the learning management system for manufacturing? This solution was designed long ago to train employees to work on equipment and machinery and deliver quality services and collaboration to clients. Learning flexibility and accessibility are core features of LMS for the manufacturing industry. With a manufacturing LMS, companies can create training initiatives and resources to automate the training process and improve the performance of employees. LMS is not a new solution, but it is an effective one. It allows the company to reduce its expenses on odd processes and provide a complete resource library of tools, modules, and sessions with related requirements and objectives. By enhancing their expertise, the employees can improve their operations and share their experience with colleagues.

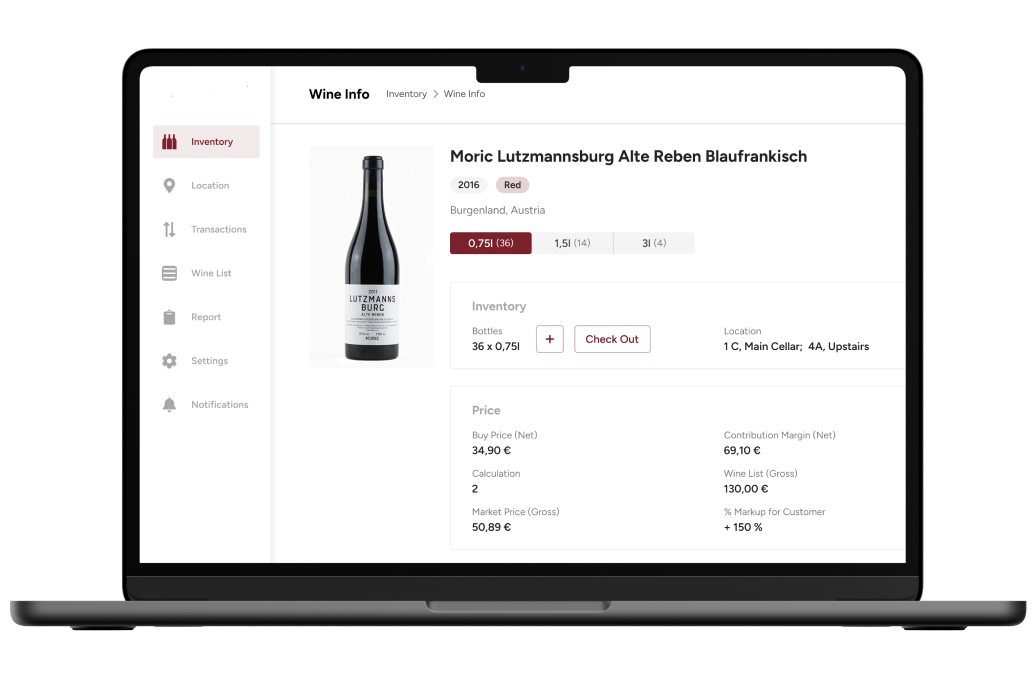

LMS provides custom-developed training materials for employees and delivers reporting and analytics to allow business owners to assess the employees’ progress (read-learners). Knowledge management is one of the core objectives of LMS for manufacturing companies, which collects and examines data on the educational sector of the business to guarantee that all employees keep pace with one another. When integrating LMS in manufacturing, you, as an owner, have a guarantee that all employees receive proper training. Moreover, this is a beneficial solution for onboarding new employees, ensuring no critical instructions like employee roles, fire safety, or work rules are missed. Manufacturers can use LMS to ensure everyone follows the same guidelines and operational updates. It’s all about the significance of Learning Management Systems.

Top Benefits of an LMS for Manufacturing Business

Centralized training

Combining employee e-learning and the company’s ROI equals workers having a safe workplace, a stable product, and proper compliance with regulations. Centralized training benefits a company by allowing managers to store the same content in one place, edit and update the information, and re-deliver the desired material. Moreover, statistics collected from the LMS will be able to show the company’s return on investment through analysis of employee use of the system.

Learning at any location

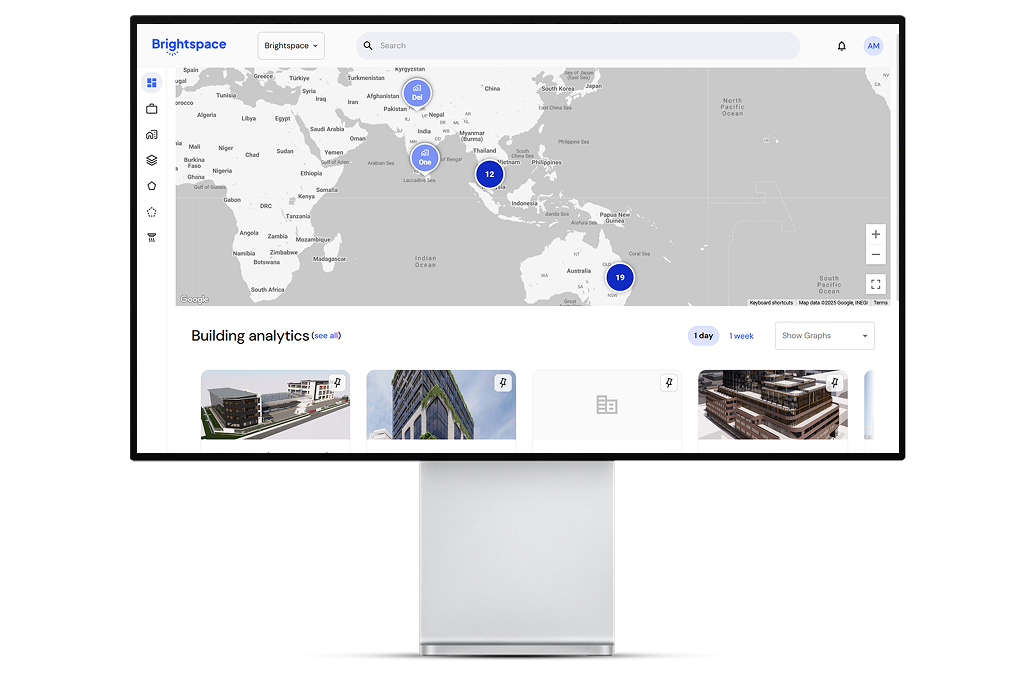

LMS becomes highly beneficial if manufacturing has several units or facilities in different locations. The opportunity to train various skills at work is often critical for employees. But if the facilities are in multiple locations, it’s a challenge. LMS, instead, can provide all parties with a seamless learning process at different devices and locations through its cloud-based access to training.

Improved business analytics

Getting reports about the employees’ course completion is a key metric for assessing the knowledge level of the personnel. It helps employers understand compliance and knowledge gains and find areas the staff needs to improve. Managers can track the employees’ course completion rates, overdue courses, and performance through a centralized dashboard. What’s more, when integrating tests and quizzes into the end of the training courses, employers can analyze the gaps that the employee still finds challenging and help them improve.

Simplified onboarding

Employers shouldn’t spend money on training new employees. An automated training process allows them to deliver standardized training and will enable employees to join the processes flexibly and quickly.

Scalability

Scalability matters. If manufacturing is growing and scaling, the managers should regularly update their training to meet the new requirements and demands of operational processes. With business scalability, it’s critical to set customized learning features to engage an expanded group of users. Besides, the higher the number of users in LMS, the more elevated reporting solutions the manufacturers need. As the scalability increases, the system should continue functioning without any stops. More often than not, course creators may not realize the importance of system scalability, and when there comes a need to adapt to changes, there are fluctuations post-launch. Therefore, the owners should consider scalability at the development stage.

Increased customer loyalty

LMS allows you to manage not only internal personnel but also your customers. Employers may underestimate customer training LMS solutions. But especially in sectors where technology and services intersect, it’s critical to introduce clients to a company’s products and services so that they use them to their full potential. In this case, you ensure your customers understand your offerings fully and maintain loyalty and retention to your brand.

Safety and health at the production facility on-site

LMS improves safety and health at production facilities. Providing employees with a safe workplace and law adherence is important in the industrial sector. LMS provides them with unified access to training materials for situations where they should apply equipment handling, hazard communication, and emergency procedures. Well-informed employees can demonstrate compliance with health and safety industry regulations. However, when employees don’t complete safety training, the LMS platform can alert managers to restrict facility access or take some measures.

How to Choose the Right LMS for Your Business

Choosing the right LMS for the manufacturing industry is a challenging process involving many factors. You must start by clearly defining your vision, goals, and requirements. Before considering LMS software development, start by outlining the main issues you want to solve through your LMS.

Before suggesting our tips, you should note two scenarios. You can be the client who wants to develop your own solution matching your business requirements, or you can be the client looking for an existing solution to implement into your business processes. Our list of tips will suit you in both scenarios. The main thing for you is to understand the essence of our offers and adapt them properly to your situation.

So, let’s start.

1 List the desired features you want to incorporate (if you develop) or see (if you’re going to buy) in your LMS.

Before making a list, search the market for existing solutions and analyze what competitors’ solutions offer, how they function, and how they engage users. Maybe, for your needs, it’s enough to integrate the existing full-fledged solutions if you only want to improve your business’s operations. Here, Keenethics can also help you with system migration and integration.

2 Consider the system’s design.

First and foremost, it should be intuitive, easy to use and understand, and have proper screen sizes. Besides, it should be web-adaptive for any devices and servers. If you want to get the most out of it, it’s beneficial if you can integrate this solution with other tools your business uses.

3 Evaluate your vendor.

If you have several vendors, see their expertise by assessing their portfolio in developing LMS for manufacturing companies. Evaluate their main offers and approaches to the client case studies. The core aspects you should focus on are industry presence, development, communication approach, and reliability. Try to select up to three vendors and then compare their approaches to LMS development.

4 Scan your budget limit.

Consider the budget once you have determined your vision of the right LMS. Note that a professional development company can help you integrate or develop a successful LMS even with a limited budget. Then, based on your requirements, needs, and budget constraints, you can agree on the relevant project for your scenario. Nothing is impossible when you partner with a dedicated team; they must know how to offer the best for clients. The pricing models of different vendors differ, so you have many variants to choose from.

5 Decide on the LMS implementation model, whether cloud-based or self-hosted.

While the first model offers convenience and maintenance by the vendors, the other one provides you with independent control over customization and data privacy. Both cloud-based and self-hosted models have pros and cons, so define your main goals and consult the development team to make the best choice for your business.

6 Implement LMS and onboard your staff.

Implementation and onboarding play a crucial role in how the system will work. The best option is to address the development team, which will adapt the solution to your processes and provide you with the best advantages. Remember, a well-structured development and implementation plan will bring your enterprise the proper experience for all stakeholders.

Why choose Keenethics? Keenethics, as a web development company, has years of expertise in manufacturing software development, including LMS solutions for different industries. Our clients choose us for our development approach, agile methodologies, and custom expertise we can propose in various domains. In each collaboration with our clients, we offer custom approaches depending on the client’s initial requirements and objectives. We have dedicated in-house teams who provide the best assistance, from the initial setup and customization to long-term maintenance, tests, and updates. Our portfolio is open to our clients, so if you’re interested in assessing our expertise, feel free to check our portfolio page. Contact us to learn more about the custom LMS solutions we can provide for your business.

Conclusion

In the manufacturing sector, providing employees with all training to cope with industrial challenges and be skilled to operate and adapt to diverse business needs is critical. You must thoroughly approach finding the right LMS for the manufacturing industry to equip your employees with all the knowledge. Consider the features we mentioned, which you should look for in a successful LMS. If selecting sufficient features, you can be assured that the LMS you choose can fulfill your needs properly. Also, consider our tips for looking for the right LMS. Reducing the skill gap means implementing or developing an effective solution to provide personnel with on-time and on-demand training support.

Contact us for help in LMS software development for your manufacturing business. After listening to your requirements, we’ll employ a tailored approach to ensure your LMS isn’t only flexible and innovative but seamlessly integrates with your existing manufacturing systems. There is one step from hiring our services to releasing your digital product. Contact us to learn how we can help.

Trust in Keenethics, a leading provider of manufacturing LMS solutions, to guide you toward long-term growth. We are ready to listen to your project ideas and offer the best development initiatives for your secure manufacturing business environment.