Big Data in manufacturing is a technology that is likely to be highly transformative in the upcoming years.

The reason for this inference is simple: Big Data allows one to find interesting insights about the manufacturing process. These valuable insights can later be used for upgrading the majority of the work-related processes. Hence, it’s not surprising why so many experts on the market are willing to invest in it. The ability to improve one’s processes is among the most highly sought-after aspects of modern manufacturing. For example, Big Data can help understand if a certain factory is efficient or not, and so on. In this light, the main goal of this article is to understand the importance of Big Data software development for manufacturing.

What Does Big Data in Manufacturing Represent?

Big Data in manufacturing is a rather simple concept. It stands for the use of modern computer devices to collect information about the smallest aspects of the production process. Why is this so vital? Using such data, you can improve many elements of your everyday work. For instance, Big Data can show whether upgrades in product design are efficient or not. It’s also capable of highlighting if certain groups of workers are good at their jobs or not. In short, Big Data in manufacturing offers a tremendous amount of information on minor aspects of your work that can push you towards creating small everyday gains. These elements can eventually become the core of your competitive edge. In this regard, the science behind 1% everyday gains is confirmed: for instance, the British cycling team won Olympic Gold using this approach.

Why Is Big Data So Vital For the Manufacturing Industry?

Big Data is so vital for the manufacturing industry for one simple reason: it allows one to upgrade production efficiency and save tremendous amounts of resources. Firstly, you can use Big Data to find unnecessary waste in your manufacturing process. This is highly necessary because such an approach helps save resources in everyday scenarios and minimize the costs put forth by your firm. Secondly, Big Data in manufacturing may highlight large-scale problems with various operational processes. For instance, you can find out how much certain teams produce per hour and then make judgments on their long-term efficiency. Lastly, Big Data is essential for understanding your supply chains. By knowing microdecisions in it, you can make data-driven choices capable of promoting approaches such as just-in-time. In short, the core benefit of the technology is the ability to know microdecisions in manufacturing. These microdecisions are one of the best sources of information for promoting some form of marginal improvement described in the section above.

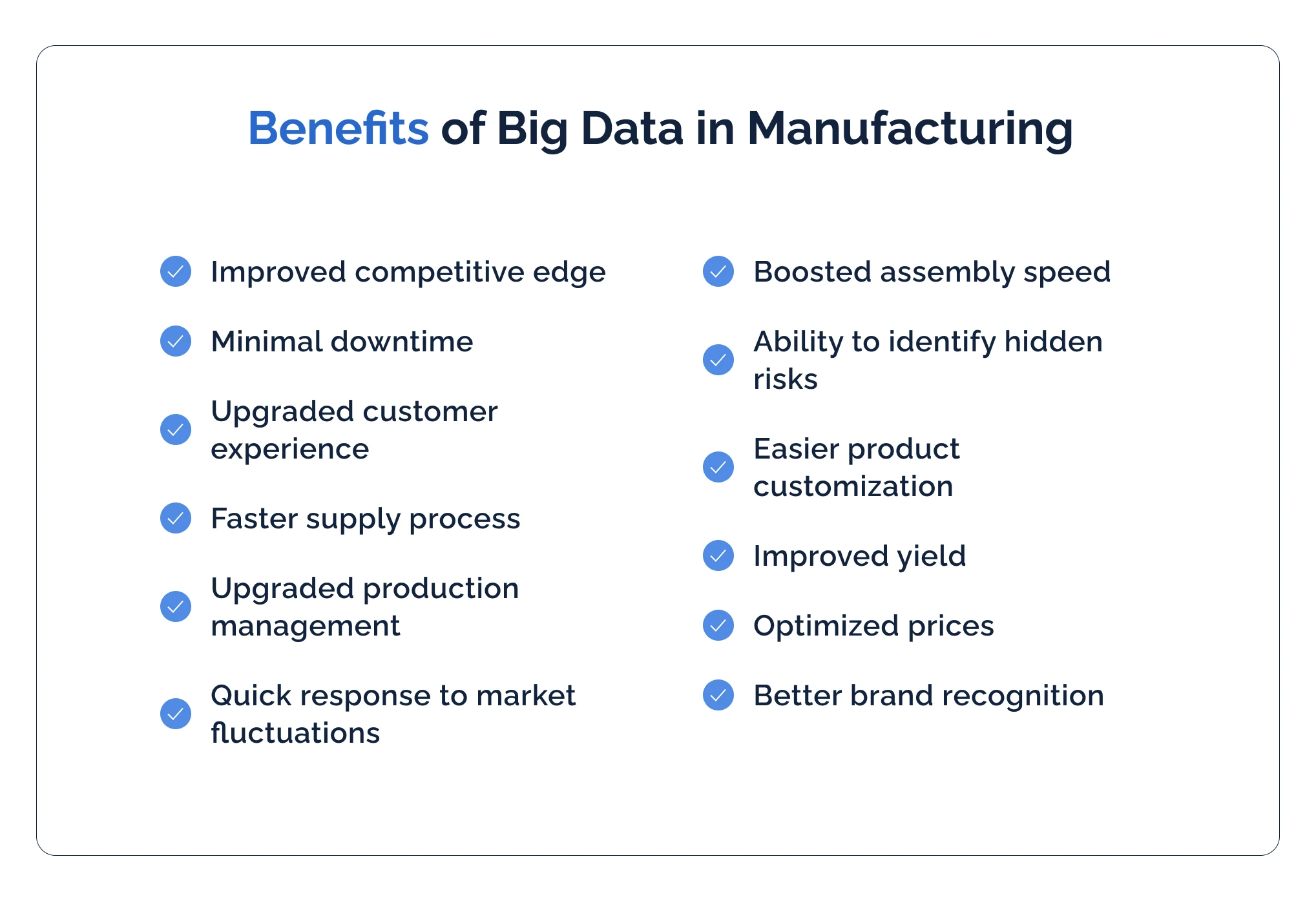

Benefits of Big Data in Manufacturing

Big Data in manufacturing is among the most important aspects to consider for any firm. Therefore, let’s review how this aspect can give you major benefits that will upgrade the capabilities of your firm in the manufacturing industry:

1. Improved competitive edge

We’ve already mentioned the example of the British Cycling Team, which won Olympic Gold through a process of small-scale improvements. Big Data in manufacturing is primarily about this set of improvements for your firm. What can you do to gain a major competitive edge? Big Data can highlight minor problems in your processes that are usually not visible to outsiders. Using the information on these minor concerns, you’ll be able to create significant improvements to your processes like demand forecasting. As a result, we believe that Big Data is one of the best ways to gain a competitive edge in the modern business world. It can give you insights that none of the competitors on the market have.

2. Minimal downtime

Downtime can be both visible and invisible among various firms. On the one hand, visible downtime typically happens with big machines, which drive the entire production process. On the other hand, however, there may be smaller, non-visible downtime, which falls outside of the view of human estimates. What is this invisible downtime? For example, it can involve small periods of idleness during the production process, which happen due to a slow supply of resources. Our experience shows that such downtime is common and can significantly undermine operational efficiency for many firms. In many situations, unexpected failure of various businesses may be a direct outcome of such problems.

3. Upgraded customer experience

Customer experience in manufacturing greatly depends on the speed of production and its quality. Let’s imagine a firm producing cars according to customer demand. Slow manufacturing processes can lead to major customer dissatisfaction. Car production can take multiple months and, consequently, lead to the cancellation of an order. In turn, an investment in Big Data in manufacturing can greatly improve the processes. It’ll be possible to find customers who are more likely to cancel orders and, more importantly, upgrade the overall production processes through manufacturing analytics. As a result, the technology in question leads to significant upgrades in customer experience that prevent long-term issues with customer satisfaction.

4. Faster supply process

Supply processes can also greatly benefit from investments in Big Data. In this respect, the manufacturing space upgrades in Big Data work in several ways. Firstly, you can find minor downtime in the supply of certain goods. This is vital for improving the ability of your firm to speed up supplies. Secondly, Big Data allows finding if certain companies in the manufacturing business are capable of supplying your firm on time in general. In this way, you get to find which companies are the fastest at supplying this or that type of ware. Lastly, supply chains also improve because there’s no waste of incoming resources. The likelihood of a certain resource being without use is greatly reduced when you have full insights into your production processes at the manufacturing stage.

5. Upgraded production management

We’ve already mentioned the benefits that may stem from the investments into Big Data in manufacturing. These benefits will have to be realized through a cohesive group of individuals in your firm. This group of individuals includes production managers of all types. Improvements in production processes will occur in the following way: the managers will use the system to analyze information about your processes and then make significant judgments on certain types of improvement for your firm. As a result, you get to improve the long-term product quality in your company through the proactive interventions of the managers, who will see a clear path toward improving the positions of their departments in Big Data.

6. Quick response to market fluctuations

Market fluctuations are unavoidable in the majority of sectors. Today, the demand may be high, and tomorrow it can be very low. The best way to capitalize on market fluctuations is to use the so-called data-driven reports. What are those? Those are the analyses of the market based on the long-term observation of its trends. Here, Big Data can help you in two ways. Firstly, it can generally inform you about the trends in the market. Secondly, it can find patterns that highlight moments during which demand is too high or too low. In this way, you get to minimize the negative impacts of market trends on your firm.

7. Boosted assembly speed

You can greatly improve assembly speed with the help of Big Data. Once again, this process will occur through the ability of Big Data in manufacturing to analyze information. In this respect, you can use the following processes for upgrading your firm: analyzing the downtime during production and understanding which teams are the most efficient. This approach will help you greatly improve customer service, for example, through changes in worker productivity. One can remove inefficient processes plaguing their firm with the help of such technologies and, more importantly, boost the ability of their company to spread the most important production-oriented practices.

8. Ability to identify hidden risks

Modern production processes feature numerous risks. Thus, the best way to ensure profits is to have a clear insight into them. Here, Big Data can make predictions based on large information sets from other companies and, more importantly, your business. For instance, you’ll get an opportunity to enable so-called predictive maintenance. This type of maintenance is highly vital because it allows one to understand the most likely moments during which a particular process or machine can fail. Hence, it’s possible to promote a continuous improvement initiative by doing advanced reviews of such information. Through its use, it’ll later be possible to prevent certain risks from making sudden disruptions to your overall production processes.

9. Easier product customization

The core reason why many firms are afraid to customize their products to a great extent lies in the difficulty of tracking an increased inventory. Cloud computing and Big Data finally offer a solution to the presented problem. How exactly do they assist? Above all, assistance comes in the form of an upgraded ability to process information. It’s now possible to track more instances of various processes in your firm. Therefore, the number of wares, including custom ones, can grow. More importantly, business analytics tools, which are a part of Big Data in manufacturing, enable one to promote a realistic delivery timeline for various new projects. For instance, you’ll be able to clearly understand if a certain ware can be delivered within a desired customer timeline with the help of such resources. How is this possible? Big Data tools help analyze future trends and make long-term judgments about them.

10. Improved yield

A wide range of small improvements based on Big Data is the surest pathway to boosting production yield. In this respect, you can get major benefits by removing downtime and spreading the most powerful production practices in your firm. All this will eventually lead to long-term improvements in the abilities of your company. Big Data is the future of the manufacturing domain because it allows various firms to see whether their processes are advanced enough or not.

11. Optimized prices

One of the core trends in the market is that consumers want minimal prices. At the same time, these prices have to be at a level that will enable firms to profit. The best way to achieve this goal is to use analytics for manufacturing generated data. This generated data can be obtained through the use of Big Data. Using it, you can optimize production and supply delivery to ensure that the prices in your firm are minimal.

12. Better brand recognition

In the end, the upgrades performed through minor changes will greatly boost the reputation of the companies using Big Data. This information means that Big Data in manufacturing is among the best investments that any manufacturing firm can make. This technology is notable for its ability to improve production speed and, at the same time, promote upgraded product quality. In this light, Big Data is a path toward turning your company into a well-oiled machine capable of producing long-term consumer innovations on the market.

What Are the Best Ways to Incorporate Big Data in Manufacturing?

1. Choose clear KPIs for your business

The first step in implementing Big Data technologies is selecting the most potent KPIs for your business. You should clearly understand where this technology will lead you in terms of innovations. This is crucial for two reasons, in our opinion. On the one hand, clear goal-setting is an essential component of understanding whether your investments make sense at all. On the other hand, this approach will assist you with establishing a clear pattern of improvements that you’ll search for in Big Data, helping maximize its long-term positive impacts.

2. Review manufacturing issues

The second step you should actively consider is the analysis of problems in your business per se. You must clearly understand your areas of weakness to maximize the benefits of Big Data in manufacturing. Why is this the case? Big Data in manufacturing is notable for its capability to highlight the root causes of certain difficulties. They may lie in small processes that are usually invisible to large-scale firms. By choosing an area to focus on, you can maximize the benefits of Big Data analysis to quickly remove some of the largest issues that your business encounters in this or other cases.

3. Analyze the cost-benefit aspects of your business

You should also do a cost-benefit analysis before installing Big Data devices and sensors. Today, the patterns of Big Data incorporation are already well-studied. This means that you can get a more or less complete understanding of the influences this tool has. It’s a good idea to hire specialists who’ll be able to tell if your business will benefit from this technology as a whole. Big Data (for example, via ERPs) is costly. In this light, the best way to work with it is to understand whether algorithms are helpful at all in your use case.

4. Incorporate Big Data in manufacturing

The final step is to incorporate Big Data in the manufacturing processes. How can one achieve this goal? Primarily, through a focus on established data collection roles and, more importantly, via the incorporation of various data collection tools in their business. All in all, the core goal here is to create a clear process for collecting intelligence based on a combination of assets and human resources.

Key Examples of Big Data in Manufacturing

Several companies have achieved major positive results with the help of Big Data. In this regard, the automotive sector is especially notable in the majority of cases. So, how do some companies achieve positive results with the help of Big Data? Firstly, Rolls-Royce uses Big Data to maximize the efficiency of its car engines. It utilizes advanced models of car behavior to make long-term judgments on vehicle efficiency. Secondly, Toyota not only uses Big Data in production to speed up the majority of the processes but also adds it to the cars themselves. In this respect, Big Data in Toyota cars is notable for its capability to prevent car acceleration in cases where the driver is confused about the acceleration and deceleration pedals.

Conclusion

To summarize, Big Data plays a major role in modern firms. In our opinion, it’s among the best ways to upgrade the delivery of products as of today. What are some core benefits brought about by this technology? It can boost your ability to find errors in the production process, understand which teams are the most efficient, and, more importantly, realize how supply chains should be organized to maximize just-in-time delivery. In short, this technology is among the best ways to promote marginal efficiency gains in your firms. In the end, our opinion on it is highly positive. Hence, you can contact our company to help you create solutions aimed at Big Data analysis of manufacturing processes.

In this case, Keenethics offers a high-quality custom development solution for its clients.