Do you consider an AI solution for your factory? This article will outline the core ways to work with them.

Human workers remain the most flexible production factor in any enterprise. In this respect, humans are capable of adapting to almost any task as long as they have sufficient education. What’s the problem with using human labor? It’s often costly; moreover, a major payment for the universal nature of labor is its tendency to imperfection. We know that, in many cases, human errors are common. Consequently, the main goal of this article is to outline an alternative, which comes in the form of AI in manufacturing. These AI software solutions may take on human tasks in their entirety or, for example, act as collaborative robots, helping humans avoid errors in their everyday judgments concerning work.

What Does AI in Manufacturing Stand For?

Artificial intelligence in manufacturing is the use of AI technologies for enhancing various production processes. The use of this technology may come in many forms these days. Firstly, AI can assist many individuals in the manufacturing industry by automating tasks. Modern AI platforms know how to process visual data. Hence, they can do complex tasks that only humans were capable of carrying out in the past without major interventions.

For instance, robots that understand how to navigate warehouses are appearing en masse these days. This approach enables so-called smart manufacturing, cooperation between humans and digital IT tools in production. Secondly, AI tools can serve as assistants within the bounds of this model. Even though workers perform the majority of the activities, they analyze their behavior and offer recommendations on optimizing this or that aspect. In short, AI in manufacturing is a labor-saving and enhancing model that is perfect for promoting long-term improvements in the productivity of the main employees.

Use Cases of AI in Manufacturing

Let’s look at several major use cases that represent the application of AI in manufacturing. In this regard, we can mention the following examples of applications:

1. Bots that assist humans

The first and most important application comes in the form of bots assisting humans in their core activities. In this respect, the manufacturing sector involves many activities that can benefit from such bots. Primarily, they can oversee the production processes and provide recommendations to the workers. For instance, modern bots are more than sufficient for creating full-scale progress reports. Moreover, they can act as guides for various manufacturing facilities. For example, the workers can ask for references regarding this or the other type of tool through these systems. Modern ChatGPT already has sufficient capabilities to work as a virtual assistant for manufacturing goals. If one provides access to a database about certain car parts, for instance, it can quickly analyze it and offer concise references. We believe AI won’t replace human labor in the upcoming decades. However, it can upgrade our work-related processes and make them much more straightforward.

2. Robotic Process Automation for tedious tasks

Another major positive outcome of the AI rise is undoubtedly the so-called Robotic Process Automation or RPA. RPA involves the use of AI-based bots (both digital and physical) for the optimization of various work-related processes. For instance, RPA in finance involves the use of AI for quick form completion. In turn, the manufacturing sector benefits from RPAs in warehouses or during the production of certain parts. For example, you can create a bot that is capable of fully automating the manufacturing of a certain part. In turn, we already know that there are full-scale robots that can perform different types of warehouse tasks for their owners. Tedious processes may also involve quality control. Equipped with sensors, robotic tools can quickly review if a certain product is in a good state or not. All in all, you have many opportunities for process optimization through the usage of modern AI tools.

3. Digital twins for process optimization

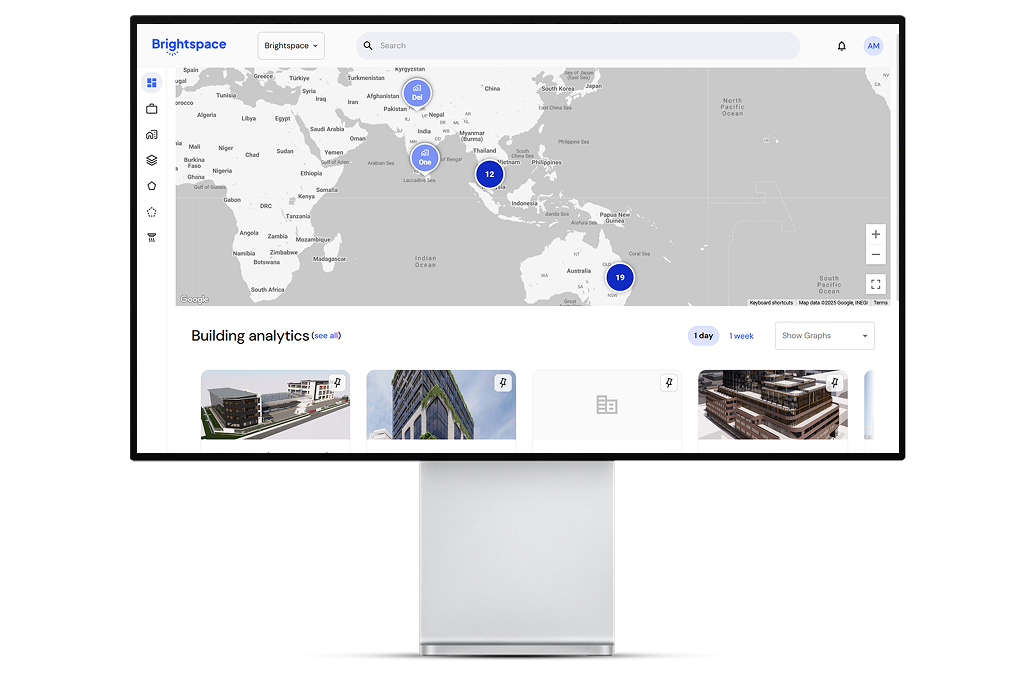

A major technological capability arising from AI is the concept of so-called digital twins. What are those? Digital twins are, as the title implies, the tools that create some sort of twin for your product. In this case, the twin may involve a digital model of your factory or, for example, of some particular product. As a result, you can analyze the impact of certain production choices on the state of your internal systems through such models.

For instance, digital twin AI tools can be used for quality assurance. You get to compare the state of a real product with digital twins through sensors, promoting advanced quality control in this way. Moreover, digital twins showcase the benefits of artificial intelligence in manufacturing by allowing you to plan major modifications in your production processes or products. For instance, you can model how a change in the production inputs will transform this or that aspect of your work with the help of these models.

4. Predictive maintenance for downtime prevention

One of the greatest threats for any business is equipment downtime, which, regrettably, tends to arise in production processes. AI for manufacturing is a strong tool for overcoming the involved challenges. What exactly does it offer? In this respect, you can try so-called predictive maintenance. AI systems can monitor the state of your equipment and the history of major problems with it to then offer predictions about times at which one should do maintenance checks on them to prevent major breakdowns. This technology is a perfect way to maximize the long-term positive effects of your equipment.

In the end, we believe that this aspect of AI usage is among the most positive. The reason for this is simple. Modern manufacturing firms work with a tremendous number of tools these days. As a result, it’s very difficult to keep track of maintenance schedules for every one of them. It’s often crucial to hire a separate individual just for this task. In this light, investments in predictive AI in manufacturing are among the best options on the market. You can greatly reduce the pressure on employees and even minimize the size of administrative staff with the use of this technology in your core manufacturing processes.

5. Lights-out factories as an energy-saving technology

Current AI tools are even enabling the usage of so-called light-out factories. This concept stands for the factories that need minimal intervention from outsiders. Consequently, they can work with “lights out”, requiring only minimal intervention from the workers to ensure that there are no defects on production lines. In our opinion, no technology right now provides a 100% lights-out experience. Nonetheless, cutting-edge technologies can optimize a major chunk of manufacturing processes. For example, many manufacturing lines that produce cars under human supervision but without major input from them exist. All this leads to large cost savings for all involved individuals. Firms save on the employment of a workforce, and average consumers get to enjoy major productivity improvements.

6. Machine learning for demand prediction

A major problem for various firms is the prediction of demand. Many wares are sold seasonally. For instance, toy factories tend to focus on the winter holidays to maximize their sales. In this light, artificial intelligence in manufacturing offers an opportunity to find moments during which it’s possible to maximize sales. If we use the example of a toy manufacturing firm further, it may fail to cover its operational costs in case it produces a certain ware for an incorrect period. AI systems can showcase the moments when parents are willing to buy certain toys for their children. Traditional sales occur during the winter season. An AI economic system may find elevated trends during other periods, too. Thus, it represents a perfect tool for the empirical analysis of various market trends due to the involved capability of reviewing data-driven insights.

7. Smart inventory management for bottleneck prevention

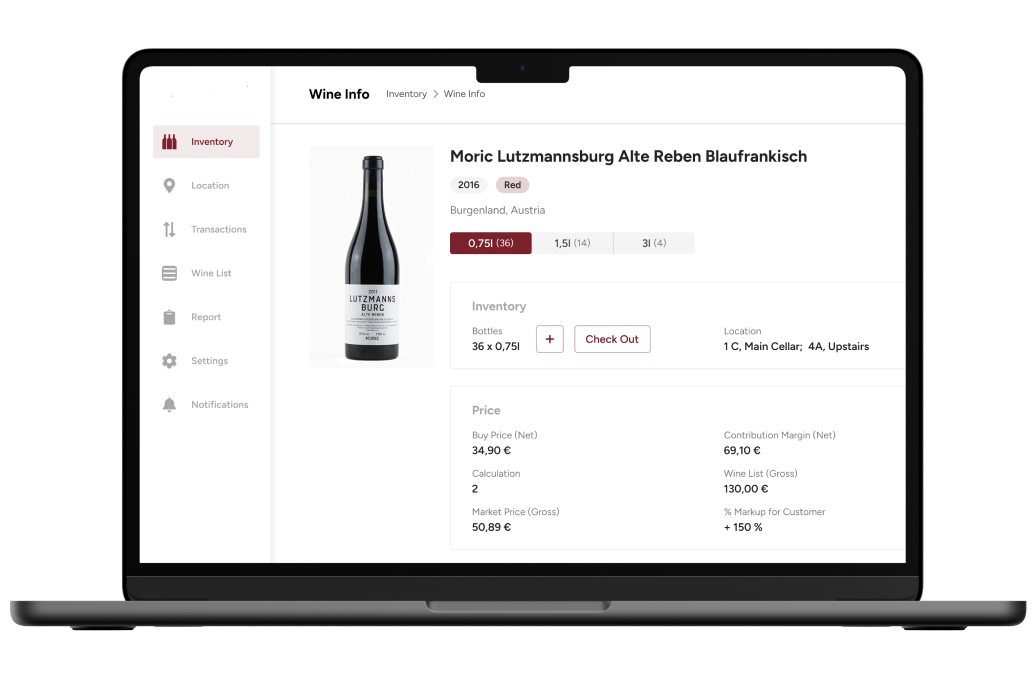

AI tools are also essential for inventory management these days. In this respect, AI in manufacturing can act as a strong monitoring tool for the core decision-makers. You can use AI to review trends in your inventory and warn supervisors about moments when a need for some particular ware arises. For instance, let’s imagine you require a particular amount of rubber. The use of AI in manufacturing allows you to monitor supply trends in automatic mode and identify quantities and order times for processes that will minimize problems with supplies. For this reason, the use of AI in manufacturing is a perfect framework for minimizing various issues with long-term supply trends in the manufacturing field. Generative design software (for instance, in the form of generative AI platforms) is crucial for preventing downtime concerns in modern business.

8. AI for improvements in supply management

Modern AI can also be used to drive positive improvements in supply management. For example, you can use it to analyze the demand for particular wares in your firm and even clearly outline the time at which this demand rises to the greatest degree. This approach will help optimize the supply chain process and make it as profitable as possible. You can find bottlenecks in your processes, getting an opportunity to raise productivity through AI applications in manufacturing. More importantly, this technology provides a way to find a wide range of excessive supplies in your business and put them to good use.

9. AI-based error detection

Modern AI is highly notable for its ability to analyze human behavior. In many cases, AIs are more accurate than humans and offer better judgments than them in certain tasks. What are those tasks? Above all, analytics of all kinds and the review of various repetitive processes. For instance, SciTechDaily reports that AI-based platforms are 30% more efficient than humans at reviewing information about so-called dark matter, which is a major concept in physics. Similarly, you can use AI to improve accuracy in other fields through intelligent automation. AIs upgrade operational efficiency by learning through trial and error in certain tasks. In this way, they gain maximum accuracy in the majority of processes. As a result, you can, for instance, use artificial intelligence in manufacturing to minimize the impact of human and machine errors on the quality of your wares.

10. Improving product development speed

Lastly, modern AI has a powerful impact on product development capabilities. In this regard, the manufacturing market is currently full of solutions that allow automation of the very process of product creation. For example, there are generative 3D modeling tools, which can help upgrade the look and feel of your object. Currently, the technology is in its infancy, as it’s mostly applicable to design rather than internal functioning. Nonetheless, if you offer a clear set of factors for product safety, for instance, an AI in manufacturing is already capable of outlining whether it’s efficient or not. Therefore, AI-driven manufacturing is only a question of time: we’ll likely see technology of this type in the upcoming decades. Many of the future consumer goods will be developed with the help of this approach.

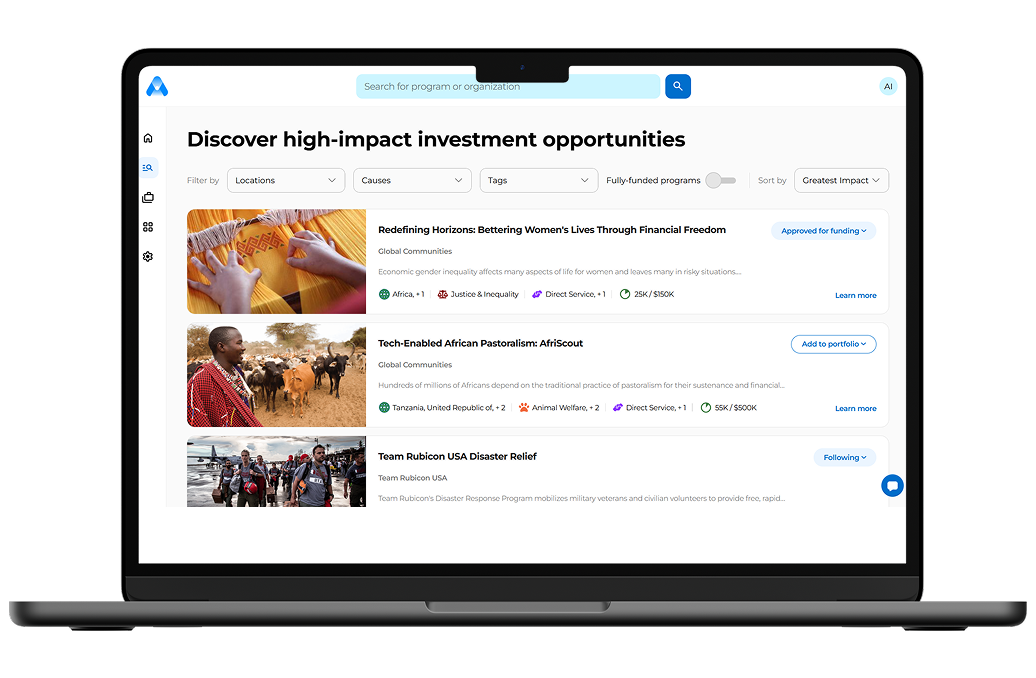

How Keenethics Can Help You With Developing an AI Manufacturing Solution?

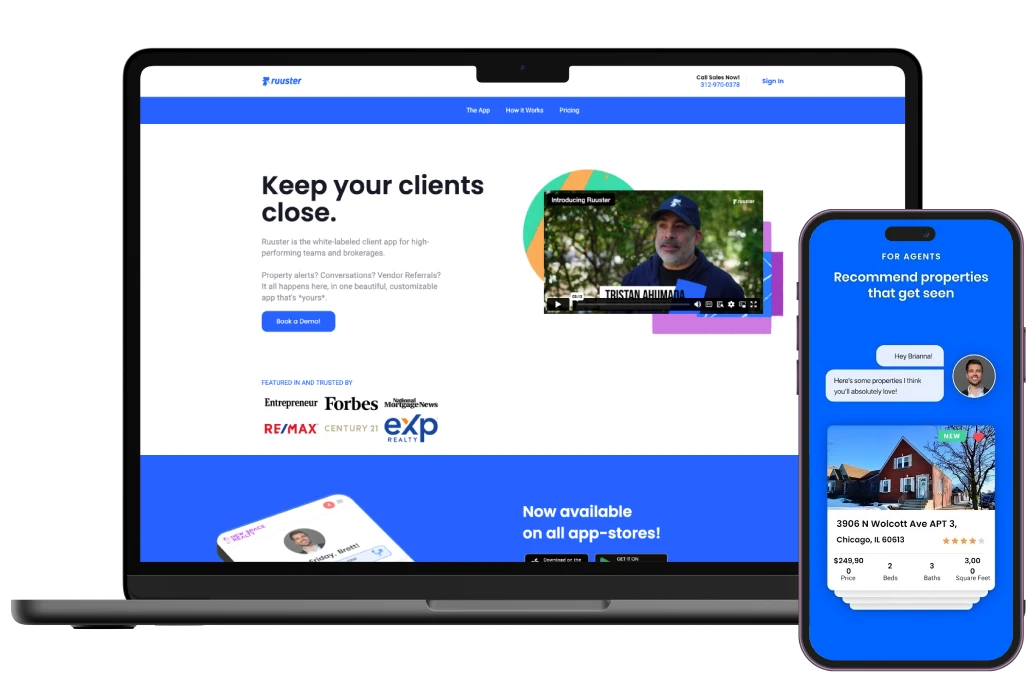

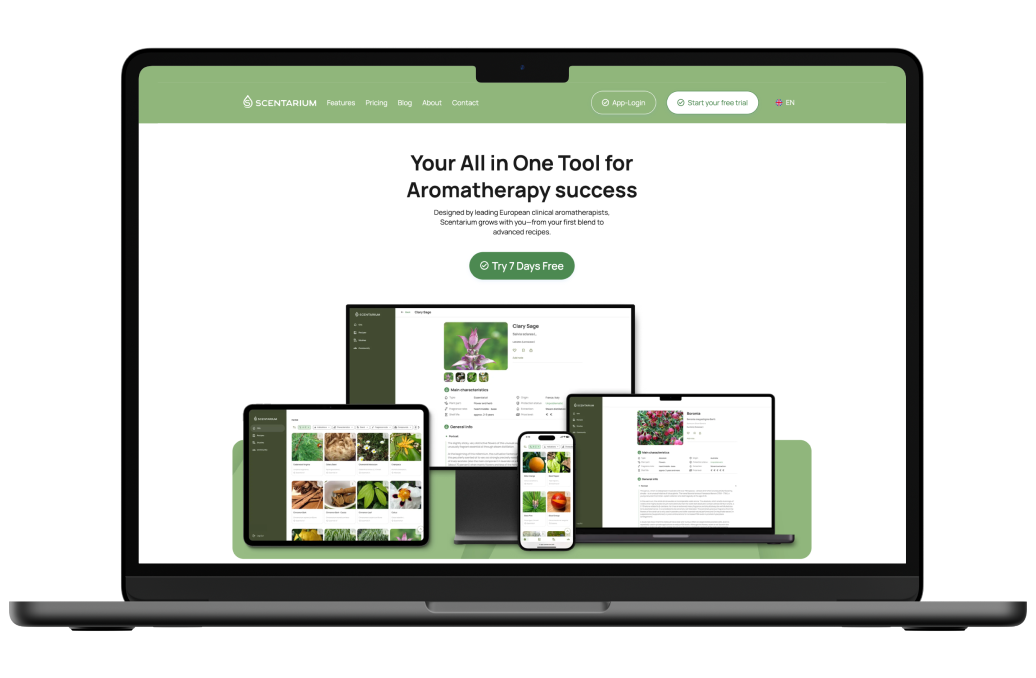

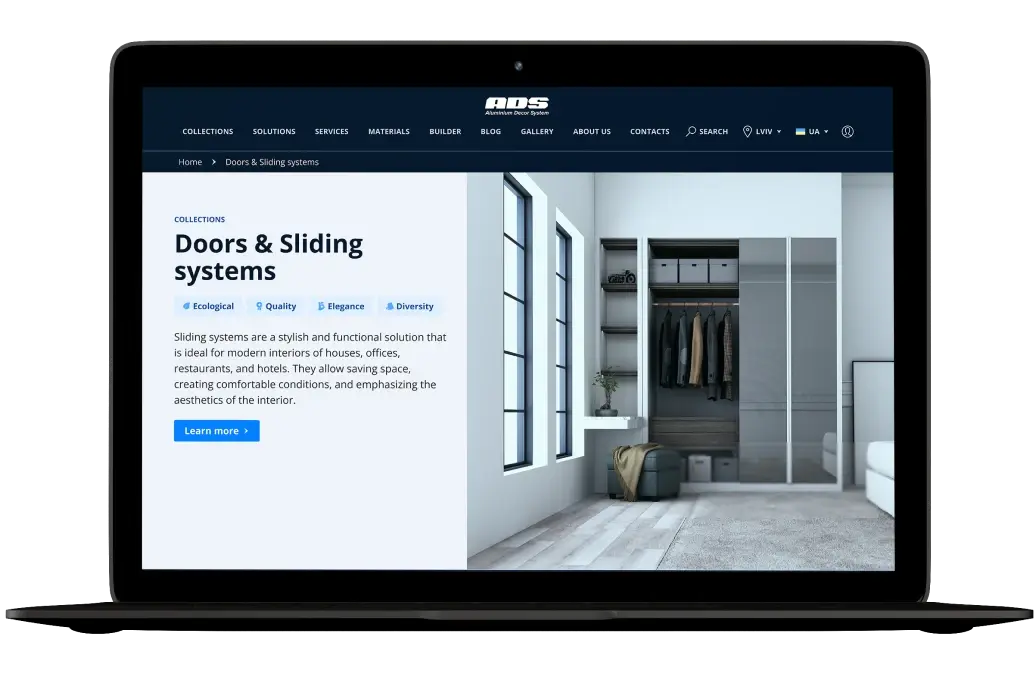

Keenethics possesses major experience in the manufacturing and AI fields, having a capability to develop software for a manufacturing company. On the one hand, we’ve helped develop multiple products with clear applications in manufacturing. They include ToolSense, which offers inventory management instruments for its customers. Oplanto is also a major product since it allows its users to create and sell 3D models aimed at the production process. On the other hand, our experience involves major interactions with AI, as multiple products developed by us use AI models. Consequently, we’re among the best teams for creating an AI-powered manufacturing solution. We have relevant expertise in manufacturing that, if combined with AI knowledge, will be essential for creating a strong AI-powered manufacturing tool for you.

FAQs

What’s the use of AI in manufacturing?

The use of AI in manufacturing is the application of artificial intelligence technologies in the core processes performed by manufacturing firms. For instance, you can use AI to predict customer demand. Moreover, it’s possible to use AI in manufacturing to analyze errors and, thus, improve customer experience through better quality of wares.

Is there a way to use AI to improve product quality?

In our opinion, manufacturers can use AI to improve product quality. The reason for this choice is simple: capable of learning through trial and error, artificial intelligence in manufacturing ultimately makes fewer mistakes than humans. Therefore, it’s a perfect tool for equipment automation, and, generally, quality control. In the end, you can use those tools for error analytics that will boost the overall quality of the presented goods.

Will AI be the future of manufacturing?

In our opinion, AI will undoubtedly be the future of manufacturing. It’s capable of real-time error analysis, which prevents many problems in the production creation phase. More importantly, it can upgrade many operations by automating them. Hence, most businesses will undoubtedly apply tools of this kind, considering their long-term benefits.

Our company can help you with such a project!