This article continues a discussion of software for the manufacturing industry. In this case, we’ll look at the oil and gas sectors.

Oil and gas industries continue to be highly vital, even despite the rise of renewable energy. Yes, renewables will most likely reduce demand for various fossil fuel businesses. Nonetheless, we believe that fossil fuels will remain a significant part of the human energy balance for many years. Fossil fuels are easy to use and, hence, they’re a perfect way to enhance energy security for various businesses. In this respect, gas companies are likely to be especially favored due to the simplicity of transporting and using it as a source of energy.

Considering the rising demands for sustainability and energy efficiency, modern gas and oil companies need to actively think about major investments in resource planning. A solution exists for this goal: Enterprise Resource Planning. Hence, the main aim of this article is to review the concept of ERP for the oil and gas industry and assist the readers with installing software of this kind.

Why Do Oil and Gas Companies Need ERPs?

Modern oil and gas companies need ERPs for multiple reasons. Their key features involve several aspects that are highly vital. Firstly, ERP systems allow one to control the usage of resources. Oil and gas are costly; thus, any resource losses may be highly detrimental to company finances. Secondly, a major reason to use ERPs is their capability to analyze the journey of certain wares. Let’s imagine you want to sell a particular brand of oil. In this case, an ERP can easily track the tendencies surrounding it. Lastly, ERP frameworks are also essential for the goal of tracking the workforce. Various oil and gas reserves are changing all the time. In this light, you need to clearly understand where this or another group of workers is situated to make adequate decisions on its deployment.

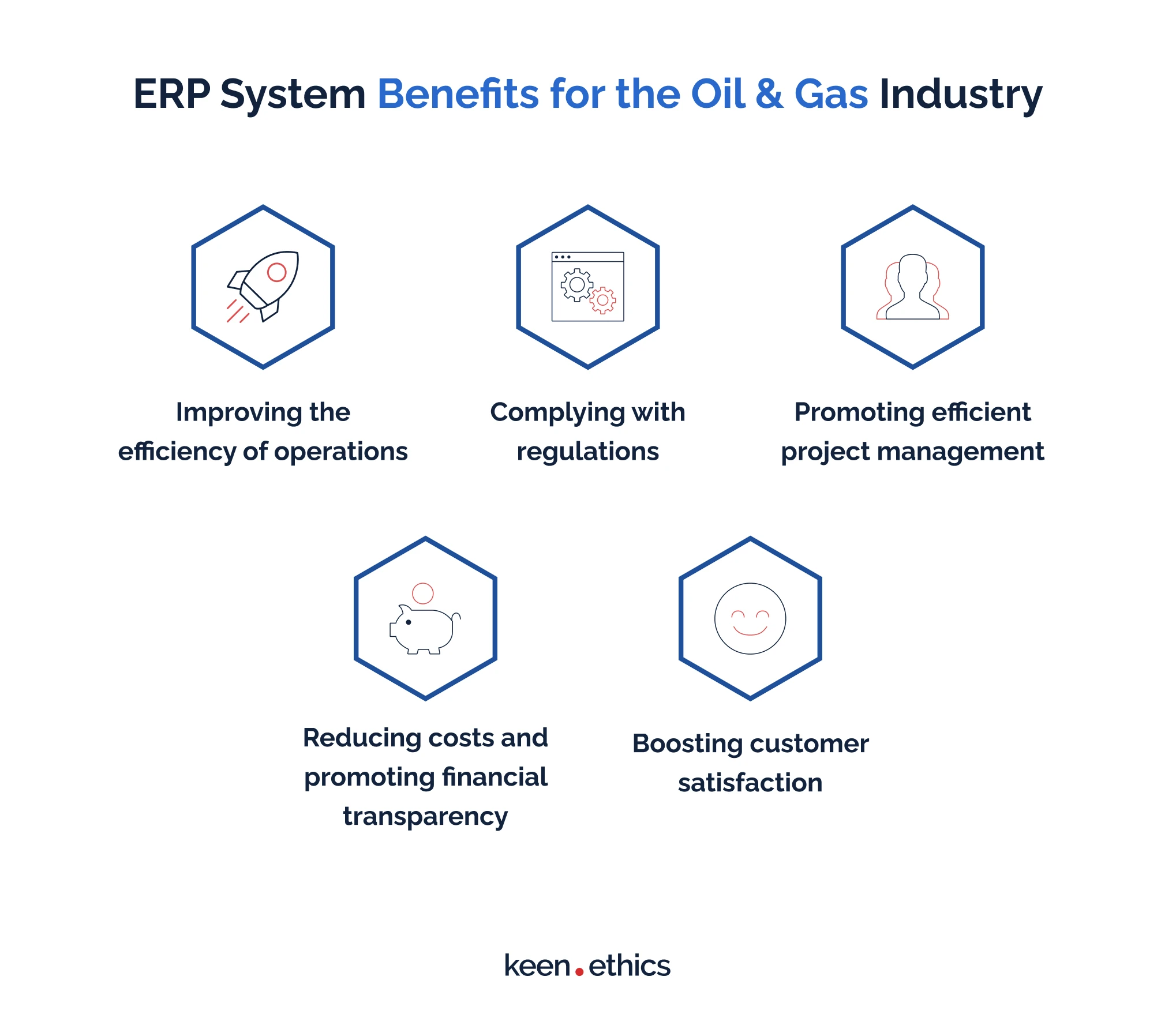

ERP System Benefits for the Oil & Gas Industry

ERPs have a tremendous number of systemic benefits for the oil and gas industry. In this section, we’re going to review those benefits in depth.

1. Improving the efficiency of operations

The first reason to invest in ERP frameworks is the ability to make informed decisions about various operations. For example, an ERP for the oil and gas industry can help you calculate how much money this or another facility brings in. Using this information, you’ll be able to find organizational gaps in productivity and have an opportunity to upgrade the management of resources in varying cases. ERPs may also offer detailed breakdowns of the productivity of particular workers with the rise of modern AI technologies. Knowing this information, it’s now possible to assign the best employees to the most important points of a business’s operations. Hence, ERPs herald the age of elevated efficiency in modern enterprises.

2. Complying with regulations

A major challenge for many businesses is regulatory compliance. In one way or another, it’s essential to follow the guidelines offered by certain governments. The inability to do so can result in major negative impacts on firm finances. Consequently, one needs a tool that would minimize the risk of encountering some penalties. In this regard, the relevant penalties are usually an outcome of the problems with instrument standardization in a business. For instance, let’s imagine you have a separate tool for inventory management, finances, and, more importantly, human resources.

All those tools may require significant efforts to interconnect information between them. In the end, the problem will eventually result in the loss of data and major challenges with its transfer. An ERP solves this problem once and for all because it presents all vital information in one place. You can manage every resource of your company from a singular location, avoiding any risks of misrepresenting information in any form.

3. Promoting efficient project management

In the end, an ability to access large repositories of information becomes central to promoting efficient project management. ERP systems are notable for their ability to record all key financial operations. Hence, they enable managers to have a full overview of the company’s finances and activities. This aspect is essential for ensuring a high-quality approach to the management of projects. Why exactly? Full access to various kinds of information makes it possible to accurately assess the quality of this or another decision in business.

Consequently, the overall quality of project management rises to a major degree. For example, knowledge about product quality and product sales can have a decisive impact on customer relationship management. In this respect, you get an opportunity to track the success of every product and capitalize on the aspects that your customers want to see above all. ERPs bring about an opportunity to manage oil and gas businesses in a way that satisfies the needs of the customers the most.

4. Reducing costs and promoting financial transparency

A major positive aspect stemming from oil and gas ERP software is the ability to reduce costs and promote financial transparency. The core problem for many businesses is that they have significant costs that aren’t recorded properly. For instance, some departments may tend to buy equipment that is far from necessary for a company or is purely excessive. In this light, you can upgrade your business operations by creating a central location for data collection. Using this information, you’ll be able to track unnecessary expenses and, thus, push your business toward maximal efficiency. It’s also possible to ensure a maximum understanding of demand for particular types of oil and gas. Consequently, ERP solutions for the oil and gas industry are among the best ways to upgrade operational efficiency in the modern world.

5. Boosting customer satisfaction

Satisfied customers are the core asset for any firm in the modern world. Without truly satisfied customers, it’s impossible to achieve any success. As a result, investments into the resources that help understand customer needs and then realize them in real life are among the most important for any business. As we’ve mentioned before, many types of oil and gas products exist on the market. They fit the diverging needs of the customers: one type of gas can be perfect for one type of equipment, and another for a different sort of equipment. Therefore, strong business processes require a clear understanding of the markets for particular goods. The best way to find those markets is to understand the demand for them among customers. ERPs may collect this information and, hence, offer full insights to customers of all types.

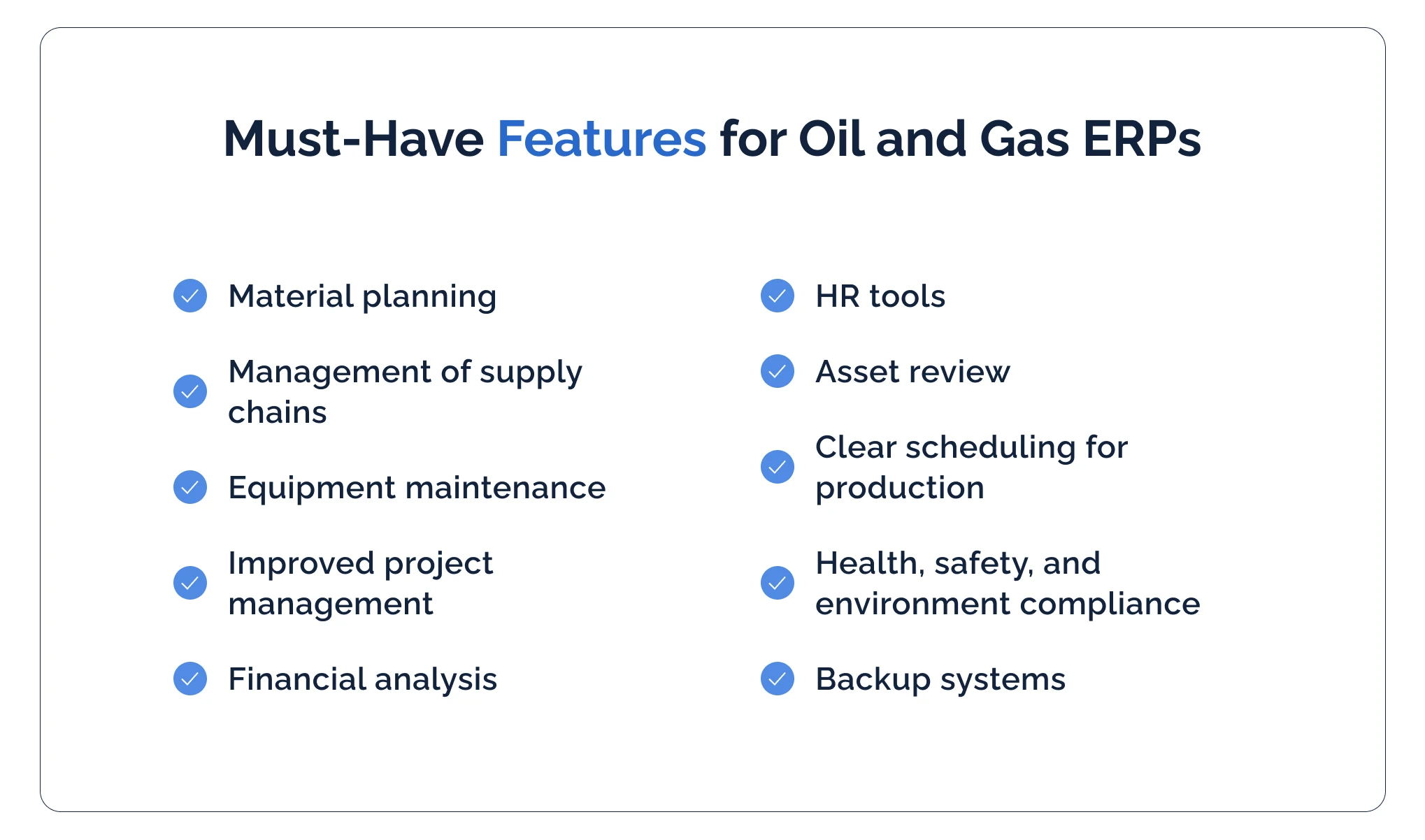

Must-Have Features for Oil and Gas ERPs

In our opinion, there are several must-have features that all oil and gas Enterprise Resource Planning frameworks must include to function well. Here is a list of those features that you should consider in your work:

Material planning

Every company requires a clear input of raw and processed materials to function. Consequently, every manager has to engage in some form of material planning while working for a business. Enterprise resource planning systems offer a strong addition to those capabilities. They provide tools capable of lowering operational costs for those businesses by doing two things. Firstly, they can analyze demand and forecast when particular materials must arrive. This approach enables so-called just-in-time supply. Secondly, they also help find locations where there’s an excessive stock of certain materials. For example, you may have a particular location in your business that uses too much drilling equipment. An ERP will help you understand this by comparing the presented information with the requirements of other facilities.

Management of supply chains

Supply chains represent one of the most important parts of any business. For instance, the steady supply of oil to certain factories is crucial because it enables companies to maximize their profits by satisfying customers. Supply chains can also play a major role in regulation control. In this regard, inadequately configured supply chains can fail to maintain environmental regulations. As a result, there’s a risk of encountering some fines. An ERP may prevent those problems by informing you about any delays in the production process, for example. Using this data, you’ll be able to upgrade your supply chains and make them as time-efficient as possible for all involved parties.

Equipment maintenance

ERP implementation in the oil and gas industry is also central to equipment maintenance. The oil and gas industries are notable for a large amount of equipment that tends to depreciate quite quickly. In this light, it’s essential to engage in high-quality equipment maintenance practices. ERP tools exist to assist in this vital process. How do they achieve this? Primarily by providing gas business with instruments that enable high-quality tracking.

One of the core problems with pen-and-paper systems in equipment maintenance is that they have a negative tendency to overwhelm the managers with tremendous amounts of information. Consequently, there’s always a risk of failing quality control by not looking into the state of particular machines on time. ERP systems solve this problem once and for all by, above all, offering comprehensive tracking capabilities. They enable decision-makers to clearly understand what tools require maintenance and which ones can wait without them. This approach, hence, saves many hours by, for example, allowing one to stop tracking various tools through inefficient methods.

Improved project management

Project management represents one more positive aspect of implementing ERP systems. In this respect, it can be vital for several reasons. Firstly, project managers receive a unified platform for reviewing the progress of all their employees. ERP systems are notable for including strong HR functions. Secondly, ERP frameworks deliver full-scale insights into company resources in the majority of cases. Thus, they represent a strong tool for finance management. A project manager should clearly understand the resources available to them with the use of this technology. Lastly, ERPs also boost operations management by enabling project managers to see all core business activities. Therefore, they represent potent tools for controlling a business in its entirety and maximizing the long-term efficiency of all its core processes.

Financial analysis

The management of finances is central for oil and gas industries. Most processes in them are costly and, thus, any problems with financial balance can have long-term negative consequences. In this regard, an ERP for the oil and gas industry is a solution to this problem. How exactly do ERPs solve this issue? Above all, by collecting all core information in one place. Here, you receive an opportunity to collect data on, essentially, all core business processes, which may serve as a strong basis for financial analysis.

The problem with traditional systems for data collection is that they don’t cover a sufficient number of processes. As a result, it’s impossible to record all company data and track the real situation in a business. In most cases, the outcomes of one or another action become evident post-factum. By reflecting all financial processes in one location, ERP tools help oil and gas companies understand the real state of their business and introduce activities that maximize its efficiency.

HR tools

Talent is also among the major resources any company should actively cherish and protect. In this respect, HR tools are among the most important methods of achieving such a goal. Typically, HR is being conducted in a way that is disconnected from other firm activities. Consequently, information about human resources typically doesn’t reach specialists in, for instance, financial departments on time. Communication is broken and doesn’t function as intended in those cases. What’s a solution? An ERP tool allows oil and gas companies to follow industry regulations by, for example, clearly understanding the core activities of their workers. In this way, every aspect of production becomes understandable to the relevant managers of the oil and gas firms.

Asset review

Assets represent one more important aspect for any type of oil and gas company. These businesses are likely to have a tremendous number of resources and tools that serve different goals. In traditional pen-and-paper or spreadsheet systems, the most widespread approach to data management is to have separate data sheets for different departments. In these cases, the probability of information loss becomes extremely high. Oil and gas ERP software exists to solve this problem once and for all. How exactly does it achieve its goal? ERPs collect information about your facility in one location. Hence, the probability of losing some assets becomes minimal. After all, multiple departments now have the opportunity to review those assets in depth. This approach bears improved efficiency for every firm on the market.

Clear scheduling for production

A big aspect of success for modern firms is clear scheduling in production. If you can optimize your processes in a way that it’s possible to bring in resources just in time, you’ll minimize the majority of distribution losses encountered by your business. In this light, our recommendation is to use ERPs for major improvements in the production sector. What can you do in this regard? For instance, you can utilize those systems to boost your production capacities. You can do this by clearly scheduling the flow of resources in your company. As a result, there’s a major opportunity to boost the overall productive capacity of your business through the use of those methods.

Health, safety, and environment compliance

Modern governments are setting an increasing number of health, safety, and environmental rules. These rules are difficult to observe because they require major employee training concerning various organizational processes. An ERP for the oil and gas industry can, once again, act as a solution. These frameworks have special modules for tracking your compliance. Since they collect all company information in one place, you get an opportunity to see if everything goes well regarding this aspect of everyday work.

Backup systems

ERP frameworks can turn into a full-scale backbone for any business. Consequently, there’s a need for real-time access to those platforms. The problem here is that some bug or any other event may lead to the loss of data and the disruption of access. To counter this issue, the best option is to make a major investment in backup systems. Here, a key stakeholder can, above all, benefit from weekly or daily records that will preserve those systems in a fully functional state. The absence of a backup framework is among the genuinely significant problems with ERP systems. We don’t recommend using ERPs that can’t back up their data in a comfortable and user-friendly way.

Key Integrations for Oil and Gas ERP Software

Modern oil and gas ERP systems can benefit from a set of integrations into the following frameworks. In our opinion, products that offer such integration have the largest competitive advantages:

Supervisory Control and Data Acquisition

SCADA systems stand for Supervisory Control And Data Acquisition. Integration with such systems can help your business solutions for ERP improve the long-term quality of collected data.

Internet of Things

The Internet of Things offers many great opportunities for asset management. For example, you can install RFID codes to collect the most vital data about your equipment. Ultimately, this means that ERP software for the oil and gas industry may become a vital source of information by integrating those tools into their data collection processes.

Geographic Information System

The ability to clearly understand the location of your assets is also an important aspect for any business that wants to produce oil or gas products. In this respect, our recommendation is to integrate those systems because they enable you to prevent the loss of assets through constant monitoring of their location.

Supply chain management

Supply chain management represents one more addition aimed at improving the performance of your business. A system for analyzing supply chains is an essential part of any company. In this regard, ERPs typically possess a module of this kind. However, integration is still crucial, as it enables you to transfer SCM information from older modules to newer ones.

Financial systems

One of the core components of any business in the oil and gas industries is the financial aspect. You most likely have a financial system if you’re working in this sector. Ultimately, ERPs typically have their financial modules. Integration still becomes necessary because it enables you to transfer information from one system to another quickly.

Health, Safety, and Environment management

The integration of health, safety, and environmental tools is also a central aspect of ERP solutions for the oil and gas industry. If you have such solutions, integration allows you to quickly transition all the data and ensure a smooth interaction between the involved systems.

Customer Relationship Management

Oil and gas companies rely on the approval of their customers concerning particular products. Hence, ERP solutions for the oil and gas industry need customer relationship management. In case your solution already has a CRM module, integration is central for transitioning data. In turn, if it doesn’t have a CRM module, integration may be vital for adequate interaction between those systems.

Human Resources Information System

The ability to review information on employees represents one of the most vital tasks for any business. Oil and gas companies need highly experienced staff to work well. As a result, an HRIS framework may be essential for their goals. Once again, integration of other HRIS solutions becomes important for maintaining the most robust systems.

Document Management

Lastly, ERP tools for the oil and gas industry can also benefit from document management and reporting. Integration of those tools may greatly speed up your transition to ERP frameworks.

Why Choose Keenethics as a Custom ERP Developer for Oil and Gas Industries?

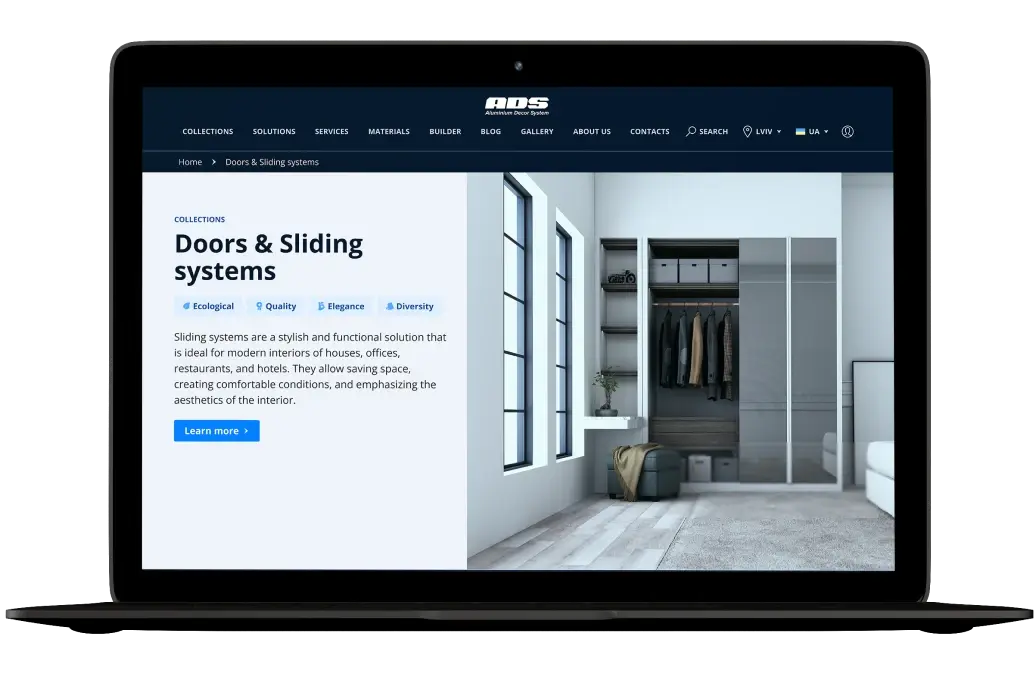

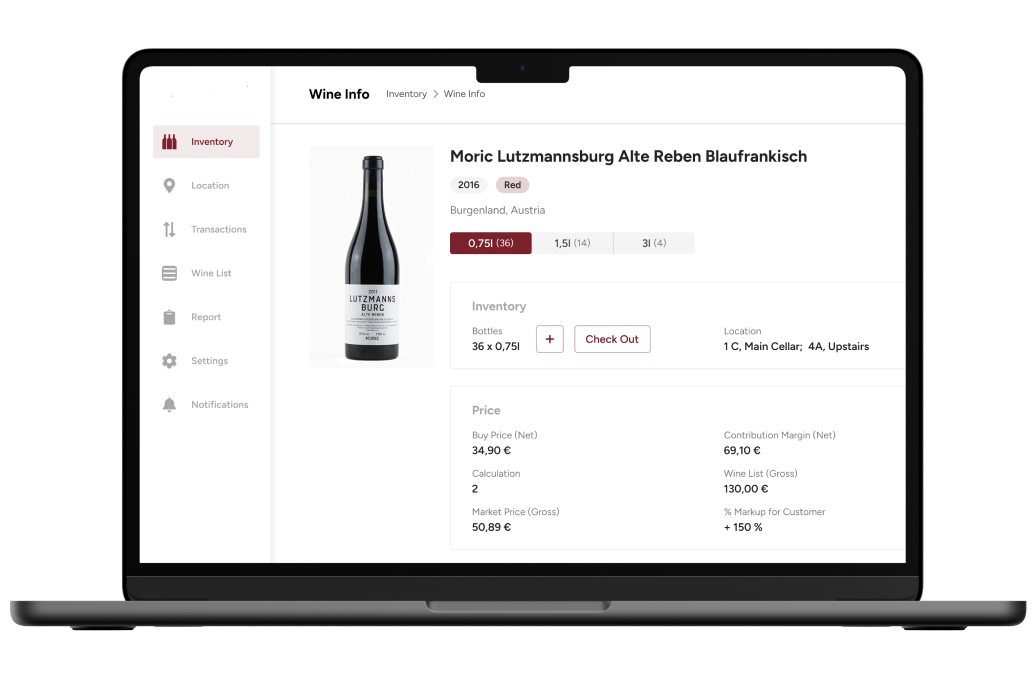

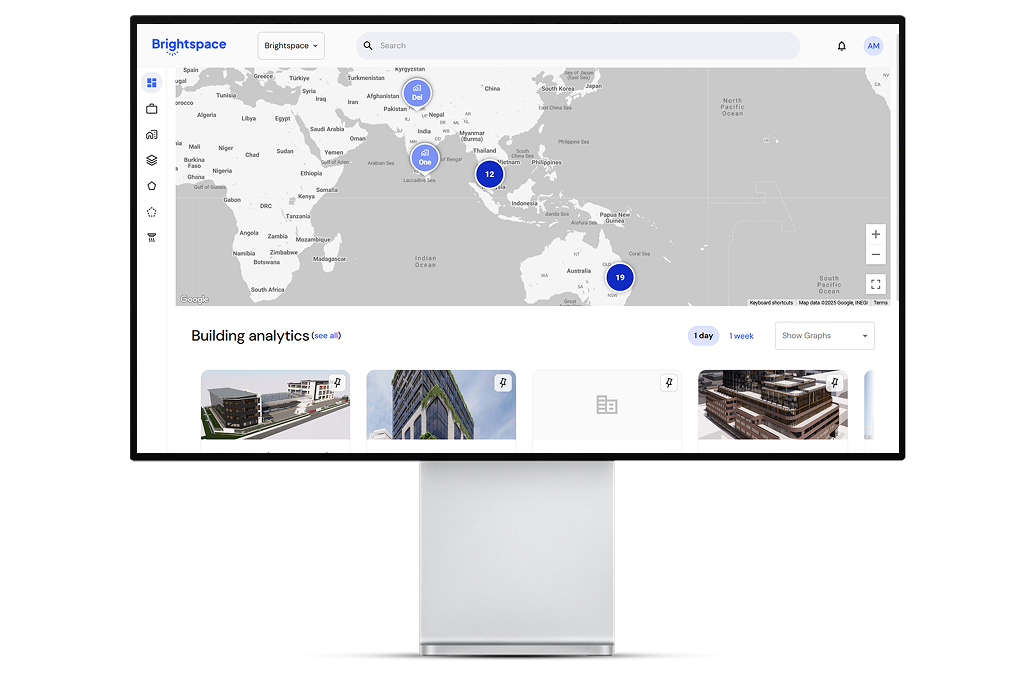

Keenethics has more than 8 years of experience in the software development market. It has developed multiple solutions for manufacturing businesses. For example, Toolsense is a project that helps manufacturing companies track their inventories. In turn, Oplanto represents a strong tool for 3D instrument management. Consequently, we currently have sufficient expertise to follow the core standards of production industries. We’re more than ready to create ERP software for the oil and gas industry.

Conclusion

To summarize, the presented information means that ERP implementation in the oil and gas industry is a highly desirable action for most companies in the relevant sector. Keenethics can assist you with the development of ERP solutions. You can contact us through the forms on this page, and we’ll respond to your inquiry request as soon as possible if you need ERP software development.

FAQ

What do ERPs stand for, and what benefits do they bring to the oil and gas sector?

ERPs stand for enterprise resource planning. These are tools used for monitoring every aspect of business processes. Oil and gas sectors can use those systems to optimize their processes as much as possible.

What’s the cost of an oil and gas ERP?

The cost of an oil and gas ERP depends on many factors. A smaller solution can cost 50 to 100 thousand dollars. Bigger ones can require millions of dollars per year in terms of investments.

What are the benefits of customization and flexibility in oil and gas ERP platforms?

Customization is essential because it allows you to install features that your company, and not any other business, needs.

What is the significance of Enterprise Resource Planning (ERP) in overseeing intricate regulations within oil and gas operations?

ERPs oversee all business processes. Hence, they can alert you to any problems with regulation adherence.

You can address our company for help!